Bambu Carbon Fiber Filaments

We hope to lower the bar to allow more people to experience 3D printing with carbon fiber and we hope Bambu filaments will be your first choice.

When it comes to 3D printing filaments, we typically evaluate them based on their printing performance and mechanical properties. Printing performance is a crucial factor that determines whether a material is suitable for 3D printing and affects the final appearance and dimensional accuracy of the prints. Mechanical properties are often overlooked, but they play a pivotal role in determining whether a material is suitable for specific applications.

For example, if you're printing parts for drones, racing cars, or machinery, the product will require basic mechanical properties such as stiffness (ability to resist deformation), strength (ability to resist damage), toughness (ability to resist impact fracture), heat resistance (ability to not deform at high temperature). The mechanical properties of these printing materials are crucial and can largely determine the life of the printed products in specific environments. The better the mechanical performance, the more the product can meet a wider range of demanding application scenarios. Filaments with excellent mechanical properties are known as high-performance filaments.

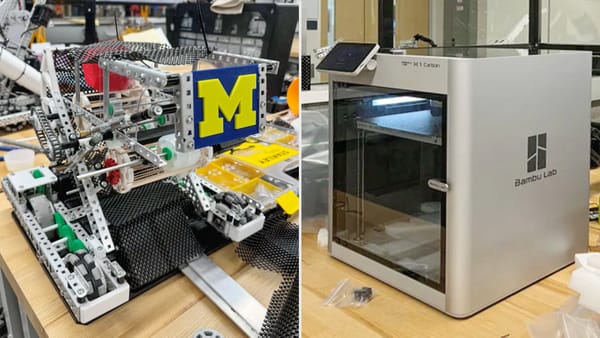

High-performance filaments were paid little attention to due to the price and limited capabilities of 3D printers on the market. Bambu Lab X1 series, as a better solution, can perfectly support common high-performance materials. In the meantime, we aim to offer a multi-dimensional system solution, including printers, filaments, and printing parameters, which ensures users can enjoy a unique experience brought by 3D printing. Bambu Lab high-performance filaments are a crucial part of this, and we're excited to offer them to our customers.

If you are familiar with carbon fiber, jump to the part of a specific filament below to learn more!

What is carbon fiber

One common solution for creating high-performance filaments is infusing fibers in a polymer base. Let's take a simple example to understand how it works.

Think of it like adding steel bars to concrete. Without steel bars, the mechanical properties of the concrete are poor and it's prone to cracking under external forces. With high-strength steel added, the concrete becomes a cohesive structure that can withstand external forces. The same principle applies to enhancing the mechanical properties of 3D printing materials through fibers, with the key being high-strength fibers wrapped in the base material.

Carbon fiber is one of the most popular reinforcing fibers, along with glass fiber and kevlar fiber. Carbon fiber is a very fine-diameter carbon material with exceptional mechanical properties like high stiffness, strength, low weight, chemical resistance, and temperature resistance. These qualities make it popular in aerospace, military, motorsports, and competitive sports. However, the difficulty of production and high cost limits its mass use.

3D printing carbon fiber filament

Imagine having 3D printing materials with some of the mechanical characteristics of carbon fiber. That would be cool, right? Current industry practice involves chopping carbon fiber and extruding it with the 3D printed base material to create the final 3D printing filament.

Consisting of a 3D printed base material and carbon fiber, what are the benefits and downsides of this hybrid 3D printing material? The benefits include better mechanical properties (stiffness, strength, etc.), higher temperature resistance, higher dimensional accuracy, the appearance texture of carbon fiber, and so on. However, it should be clear that after adding carbon fiber to different base materials, the improvement in these aspects is completely different. Some can be greatly improved, and some can be improved very little. The difference is directly related to the base itself, which we will elaborate on in the following sections. Carbon fiber materials with performance that can be improved to a very high level are called high-performance carbon fiber materials. Otherwise, we consider them entry-level carbon fiber materials.

There are also downsides to consider.

First, the printing requirements for printers are higher for high-performance carbon fiber materials. It is required to use an enclosed chamber to ensure a higher and more uniform chamber temperature. It also requires a nozzle with a higher printing temperature and a nozzle material made of hardened steel, tungsten carbide, ruby, or other super wear-resistant materials. In addition, high-performance carbon fiber materials generally have greater stiffness, meaning the filament is more difficult to bend, resulting in more likely to wear the print channel during printing.

Second, due to the fact that the carbon fiber in the filaments still retains a certain length (about 0.05-0.2mm), it is unable to melt at the printing temperature of the filaments and is relatively more likely to cause clogging during printing.

Our printers currently meet the basic needs of using carbon fiber, overcoming the first drawback, which was also one of the original design intents for our printers. The Bambu Lab X1C has a fully enclosed chamber, a hardened steel nozzle, a nozzle temperature of up to 300℃, and a bed temperature of 110℃.

For the second drawback, we optimize the printing experience through filaments and printing parameters. On the one hand, the formula for Bambu carbon fiber filaments is optimized and improved to reduce the probability of clogging during printing. On the other hand, the printing parameters are also matched and optimized. Lower printing speeds and larger nozzle sizes are recommended for printing carbon fiber materials.

Common carbon fiber filaments

Up to this point, carbon fiber 3D printing materials may be considered as filaments that can improve the appearance and mechanical performance but are not as easy to print. However, when carbon fiber is added to base materials, such as PLA, PETG, PA, etc, the degree of improvement varies. Based on their characteristics and performance, we have different classifications for them, mainly divided into high-performance and entry-level carbon fiber filaments. Let's start with the two high-performance carbon fiber filaments.

High-Performance Carbon Fiber Filaments

PA-CF

PA-CF is a carbon fiber material based on nylon. Nylon is one of the most common engineering plastics and has good comprehensive mechanical properties. It is widely used in industrial applications such as gears and automobiles through injection molding. When carbon fiber is added to this material, its mechanical properties are significantly enhanced.

Fortunately, PA-CF is also suitable for 3D printing and the prints have comprehensive properties far beyond those of ordinary PLA prints, making it one of the most common high-performance materials for 3D printing. However, nylon materials have a major drawback - high water absorption, which is very sensitive to moisture during 3D printing. Nylon filaments are prone to defects such as stringing and leaking during printing when they absorb water, which can lead to clogging and printing failures. Additionally, the strength and stiffness of nylon printed products will decrease when they absorb water, but toughness will increase. This drawback requires us to fully dry and store the material in a sealed environment when printing with this filament.

In fact, there are many types of PA, and the performance varies significantly. The most commonly used PA types in 3D printing are PA6, PA12, and some special nylons. PA6 has strong mechanical properties, but its main drawback is that its water absorption rate (about 3%) is much higher than PA12(about 0.3%). However, the mechanical properties of PA12 cannot match PA6 under dry conditions, and there are also significant cost differences between them. In summary, a good PA-CF formula needs to achieve a comprehensive balance between mechanical properties, water absorption rate, cost, and more.

Bambu Lab launched a PA-CF filament that has been specially formulated to achieve lower water absorption and higher heat resistance. We also optimized its stiffness in the design to ensure that it can be printed smoothly through AMS, and this makes it possible to print with support materials. We named it Bambu PAHT-CF.

To sum up, Bambu PAHT-CF is suitable for AMS, and has the best comprehensive mechanical performance, low water absorption, and high-temperature resistance. It is the most comprehensive high-performance carbon fiber material that can be applied to industrial fixtures, jigs, automotive components, drone parts, and more. It can easily meet various demanding use cases in daily life.

PET-CF

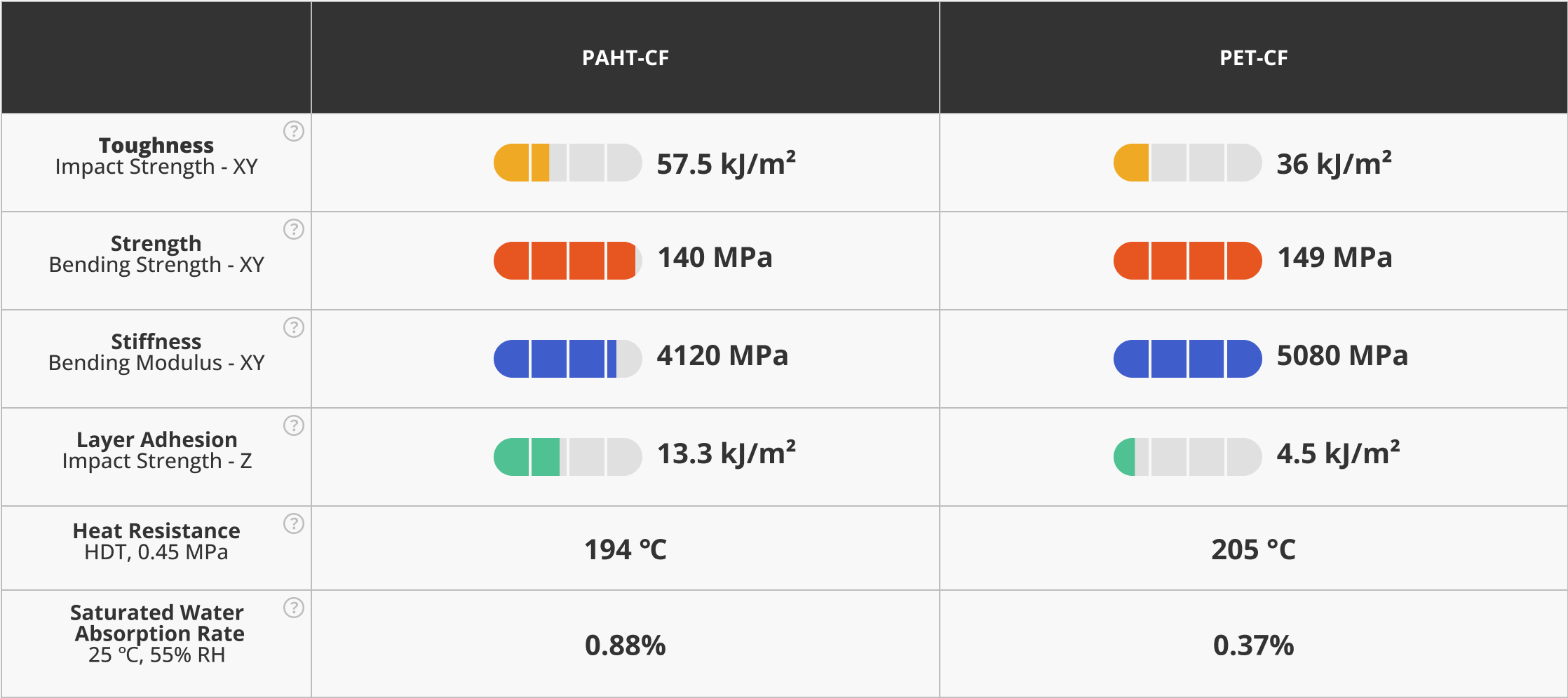

We wanted to introduce a carbon fiber material with a higher stiffness than PAHT-CF to meet users' extreme stiffness demands in certain working conditions, which is Bambu PET-CF.

Bambu PET-CF is mainly composed of PET and CF. PET is a crystalline plastic that is widely used in industries such as plastic bottles and automotive parts. It is a material with high mechanical performance, temperature resistance, chemical resistance, and other characteristics. When carbon fibers are added to PET, its mechanical performance, particularly stiffness, can be significantly improved. Additionally, it has a significant advantage over nylon carbon fiber, which is its extremely low water absorption rate (approximately 0.3%), which allows prints to maintain almost the same mechanical performance as when they are dry, even when exposed to moisture. This makes it suitable for use in humid environments.

The disadvantage of PET-CF is that it is relatively brittle, and its interlayer bonding strength is relatively poor. To address this issue, we adjusted the formula of Bambu PET-CF, and its Z-axis impact strength reaches around 4.5 kJ/m² (while the number of other PET-CF in the market is about 2-3 kJ/m² generally). The weakness of this material can also be avoided through reasonable printing processes and usage conditions. For example, when using PET-CF structural components, it is best to avoid applying force in the interlayer bonding direction and avoid excessive impact or collision, thus playing to its strengths and minimizing its weaknesses.

To sum up, Bambu PET-CF has higher stiffness, ultra-low water absorption, weaker interlayer bonding strength, and is relatively brittle. Its usage scenarios are somewhat similar to PAHT-CF, but PET-CF is more suitable for structural components that require high dimensional stability and printed parts that will be in long-term contact with water. You can flexibly choose between these two high-performance materials based on your specific use cases. If you need to use the filament from the AMS, then PAHT-CF is the best choice, as PET-CF is not compatible with AMS. The performance comparison between Bambu PET-CF and Bambu PAHT-CF is shown in the figure below.

Entry-Level Carbon Fiber Filaments

In the following section, we will introduce two entry-level carbon fiber materials, Bambu PLA-CF and Bambu PETG-CF, to meet the carbon fiber printing needs of more users. The addition of carbon fiber does not significantly improve the performance of PLA and PETG base materials. However, compared to regular PLA and PETG, you can think of the addition of carbon fiber as making them slightly stronger and stiffer, while still being easy to print and aesthetically pleasing. Both PLA-CF and PETG-CF can be used for printing with AMS.

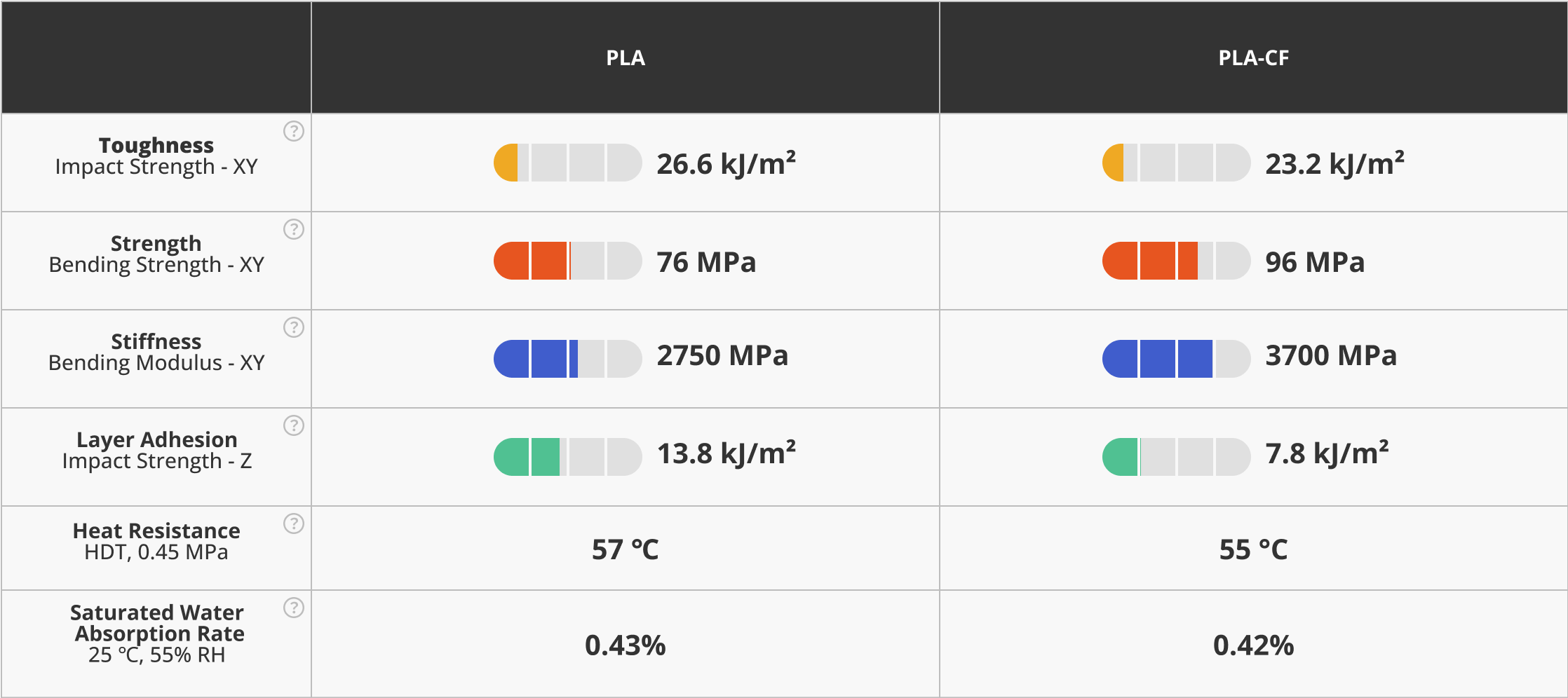

PLA-CF

Bambu PLA-CF is a filament with a matte carbon fiber texture that can greatly enhance the aesthetic appearance of products while maintaining printing performance comparable to PLA. To further optimize its printing experience, we have reduced the carbon fiber content to ensure that there is no risk of clogging even at higher printing speeds. Although the carbon fiber content is not as high as that of high-performance carbon fiber materials, its stiffness is still increased by more than 30% compared to regular PLA. Additionally, carbon fibers suppress shrinkage deformation during printing, thereby improving printing precision.The disadvantage is that these carbon fibers can affect the interlayer bonding strength of PLA-CF. However, from another perspective, the supports printed with this filament may be easier to remove.

To sum up, Bambu PLA-CF has higher stiffness and dimensional accuracy than PLA, matte carbon fiber texture, and is easy to print. It is mainly suitable for printing small tools, functional prototypes, structural components that require stiffness, and more in daily life. Its performance compared to regular PLA is as follows:

PETG-CF

Another entry-level carbon fiber material is Bambu PETG-CF, which is mainly composed of PETG and CF and has a glossy carbon fiber texture. Its mechanical performance cannot reach the level of PET-CF. The key difference in PETG is that the 'G' stands for glycol. PETG is a glycol-modified version of PET that contains small amounts of glycol as a co-monomer. The addition of glycol to PETG reduces its crystallinity and makes it more transparent, but it also reduces its strength and stiffness.

When carbon fibers are added to PETG, it can only slightly improve its strength and stiffness. Compared to PLA-CF, its stiffness is not as high, which means it has better toughness. Additionally, its interlayer bonding strength is better. In certain special cases, the high stiffness of PLA-CF can cause printing failures, but PETG-CF does not have this risk. In terms of printing experience, it may be slightly better than PLA-CF. PETG-CF also has better water resistance, UV resistance, and weather resistance, and it may provide better outdoor durability as it is less prone to degradation and aging when exposed to outdoor elements.

To sum up, Bambu PETG-CF has higher toughness, interlayer bonding strength, and heat resistance than PLA-CF, which is suitable for outdoor use, glossy carbon fiber texture, and is easy to print. If your prints require better toughness and interlayer bonding strength, you can consider Bambu PETG-CF. If you need higher stiffness, you can choose Bambu PLA-CF.

When people think of carbon fiber materials, they usually have a black appearance. For entry-level carbon fiber materials like PLA-CF and PETG-CF, we have prepared more colors, making their usage scenarios more diverse.

Our commitment

Most knowledge of carbon fiber 3D printing filaments has been covered in the above section. We will continue to add more content and scenarios in the future. For more detailed parameters, please refer to the Filament Guide and specific TDS and MSDS documents for each one. We hope this may facilitate you to choose the appropriate filaments according to your application scenarios.

Please stay tuned as we will have more carbon fiber materials and other fiber-reinforced materials to meet various demands. We hope to build a more complete carbon fiber material 3D printing experience through efforts in printers, slicing software, materials, wiki guides, and more. This may help lower the bar to allow more people to experience 3D printing with carbon fiber and we hope Bambu filaments will be your first choice.

If you have any feedback or comments about this blog, please contact us at marketing@bambulab.com.

Carbon Fiber Print of the Week

As our carbon fiber filaments are on flash sale, we'd like to know what you have printed with those filaments.

Share your Bambu carbon fiber prints on one of our social media sites including Facebook Group, Reddit, Twitter, or Instagram. Just make sure to include #BLSpotlight #PrintOfTheWeek in your posts.

We will select 6 winners in total for the print of the week with a reward of a $50 filament gift card for each one. Entries to the event will be accepted from Thursday, May 18, 2023 through Wednesday, May 31, 2023. Winners will be announced on each week of May 22 and May 29.