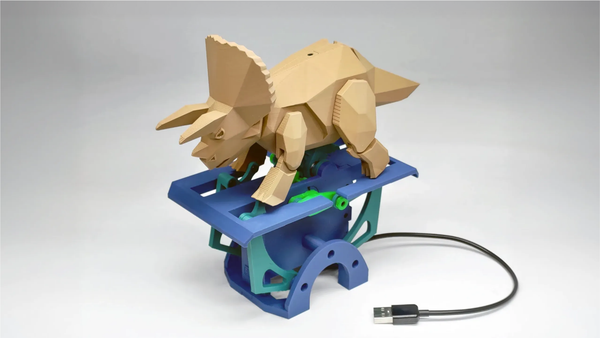

Bambu Lab H2C: where Multi-Material Vortek System meets engineering precision

Uncompromising Multi-Material. Uncompromising Creativity.

Bambu Lab once again pushes the boundaries of what’s technologically possible, setting a new benchmark in multi-material 3D printing.

The H2C represents the culmination of three years of research and development on a system that merges engineering-grade precision, automation, and reliability with consumer-oriented simplicity and a maker’s mindset.

Built around the Vortek Hotend Change System, which supports six interchangeable hotends, the H2C enables printing with up to 24 filaments simultaneously while minimizing purge waste for superior material efficiency.

When printing with fewer than seven filaments, the purge cleaning cycle can be completely eliminated during filament changes, further enhancing efficiency.

But the H2C is much more than a 3D printer for multi-color or multi-material printing - it’s a true industrial-grade performer, wrapped in the familiar consumer-friendly ecosystem used by makers around the world.

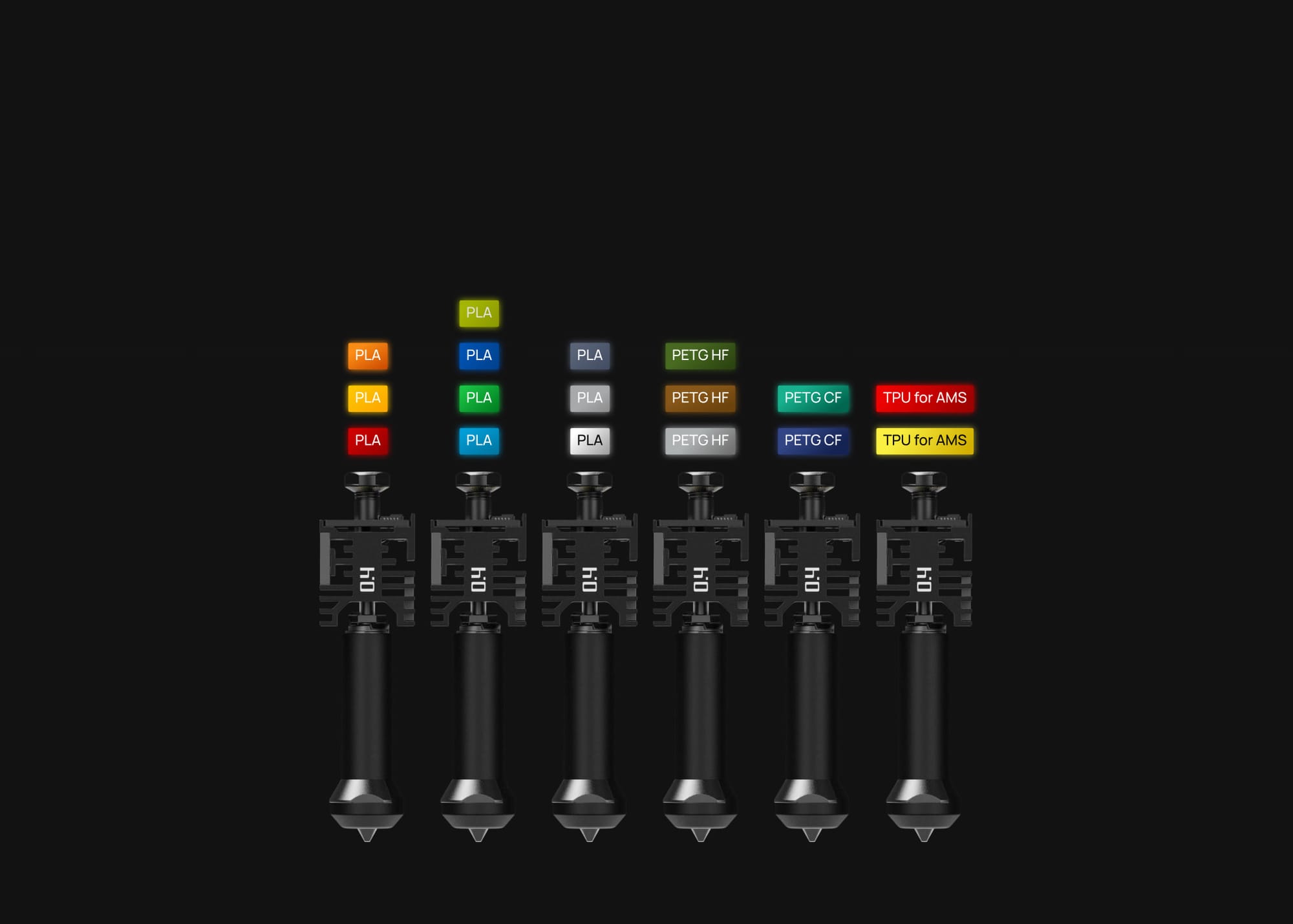

Vortek - an intelligent, purge-saving Multi-Material System

The H2C doesn’t just print - it thinks, predicts, and reacts. The Vortek Hotend Change system enables the use of up to six interchangeable, contactless connected hotends. Tool changes take only seconds, with virtually no user involvement.

The printer automatically recognizes which hotend was previously used with a given filament and, before starting a print job, suggests reusing it. This means fewer errors, less material waste, and less time spent managing the printer.

7 colors in One Go - more colors, no compromises!

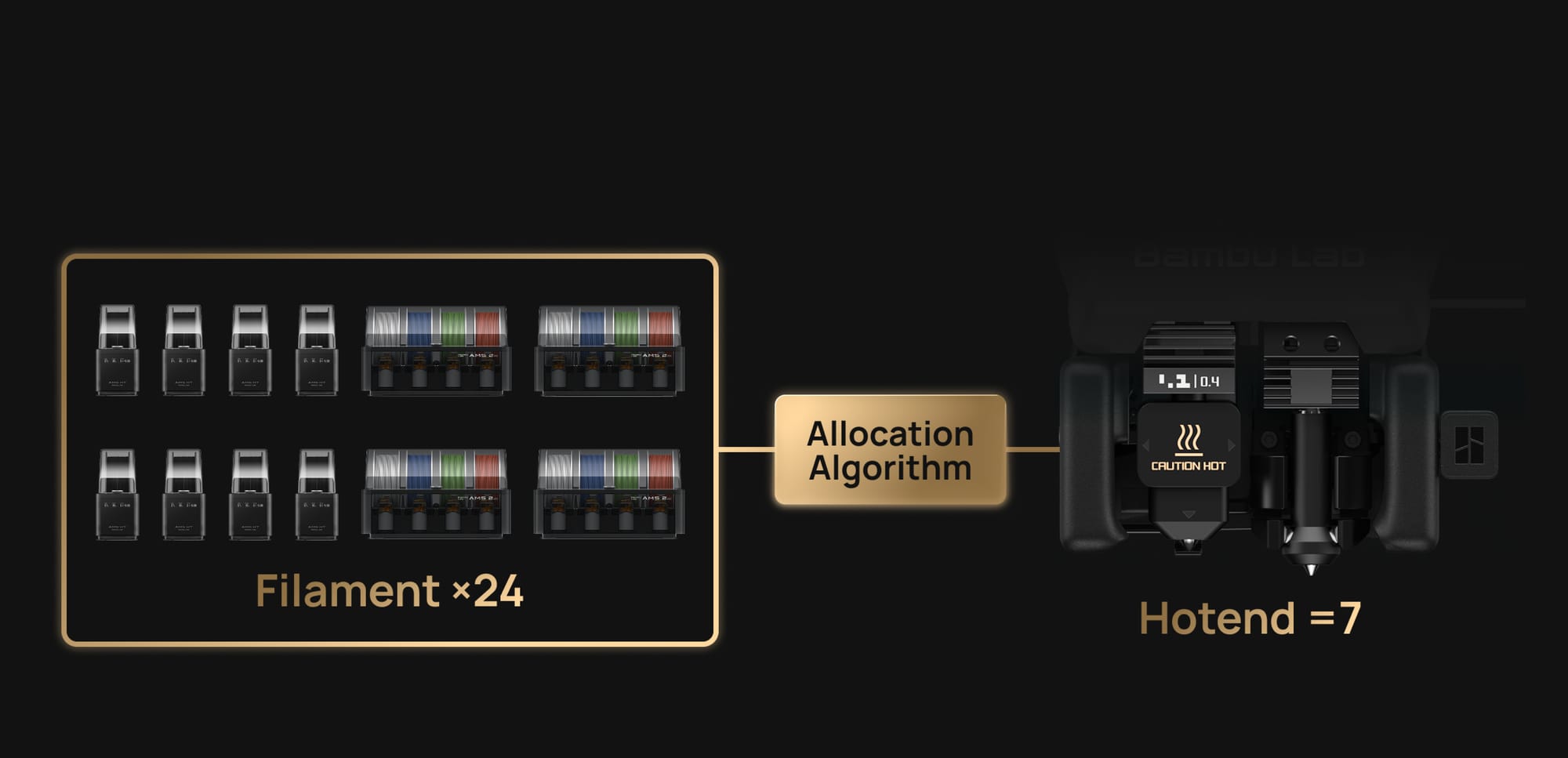

Thanks to the Vortek system, the H2C can print with up to seven colors or materials in a single job, without purge-cleaning of the nozzles. Each of the six hotends can be assigned to a specific filament.

However, when combined with the AMS system, this functionality expands to 24 filaments simultaneously!

The intelligent control algorithm automatically assigns filaments to the appropriate hotends, minimizing material consumption and purge-related waste.

“The Hotend Remembers” - intelligence that works for you

Every H2C hotend is equipped with onboard memory that records which filament it was last used with. As a result, the system automatically suggests the correct settings for the next use. This simple yet powerful feature eliminates setup errors and accelerates project preparation.

The Bambu Lab H2C is designed to minimize the time users spend managing the printer, allowing them to focus entirely on creation.

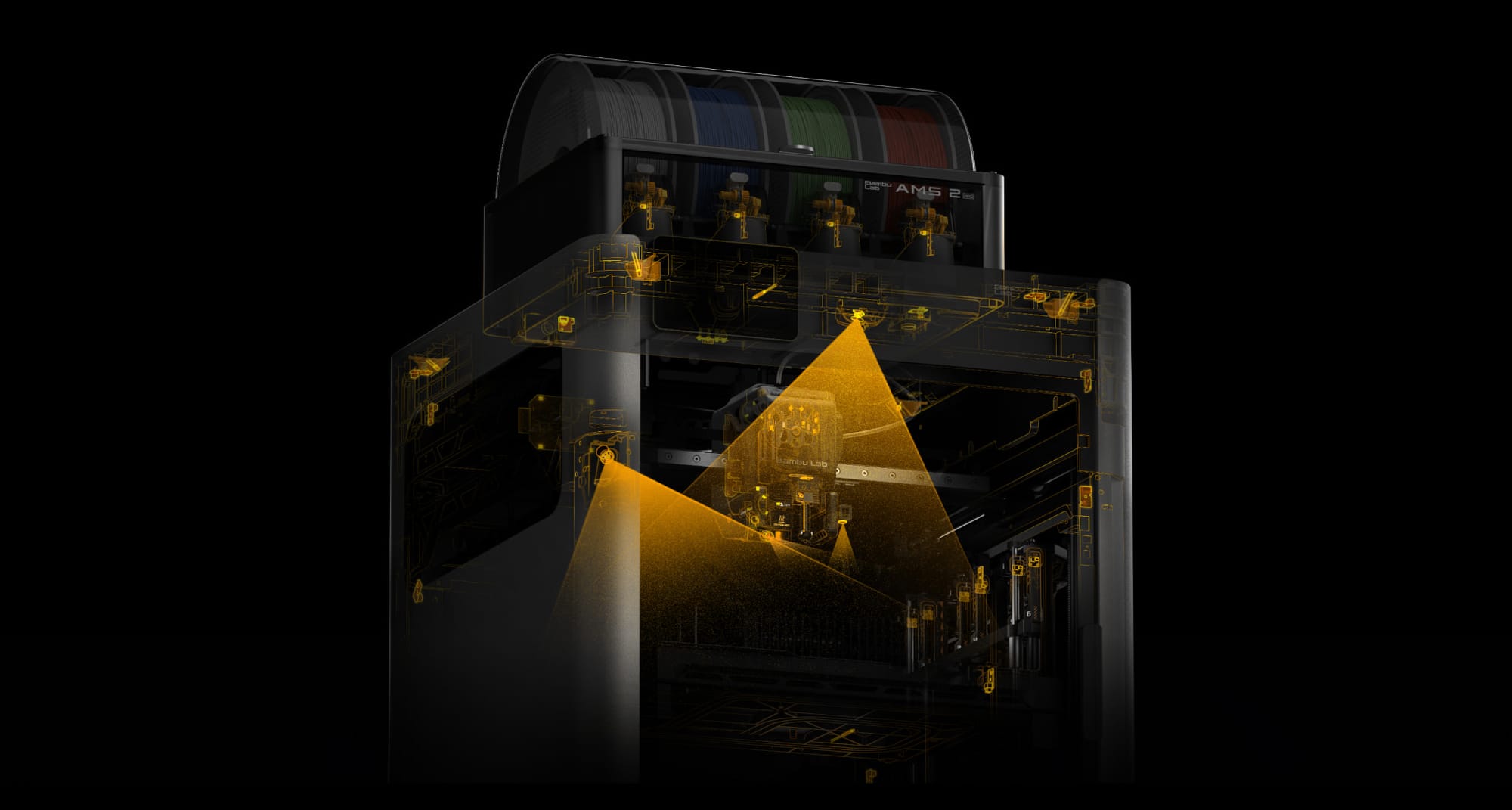

Touchless calibration, intelligent nozzle cleaning, automatic filament assignment, and hotend memory drastically reduce the need for manual intervention.

The printer handles most operations autonomously: before each print, it scans the build plate, verifies nozzle compatibility with slicer settings, and analyzes potential issues. A built-in macro lens camera monitors extrusion in real time, detecting anomalies before they affect print quality.

Additionally, the inductive heating system reaches working temperature in just 8 seconds, cutting down on print preparation time and eliminating long waits between material changes. This design boosts productivity and extends component lifespan.

Reliability as the Core Principle

Bambu Lab’s philosophy has always been focused on one core value - reliability.

In the H2C, this is achieved by eliminating mechanical connectors prone to wear and oxidation. Instead, it employs contactless, high-frequency communication between the printhead and hotend. This ensures stable data transmission, precise temperature control, and perfect synchronization across multiple hotends.

Every tool change is repeatable with micrometer-level accuracy, eliminating positioning errors and surface defects. As a result, the H2C delivers not only outstanding print quality but also unmatched repeatability - essential in engineering, production, and complex maker or cosplay projects that require days of continuous operation.

In the H2C, precision and control are the twin pillars of technological excellence.

Thanks to the Vision Encoder system, the printer achieves movement accuracy below 50 micrometers. The automatic nozzle calibration system operates completely contactlessly, compensating for mechanical deviations in real time.

Temperature and material flow control are powered by a PMSM servo extruder that generates extrusion forces up to 10 kg - around 70% higher than traditional stepper motors. The result: perfect flow control, no clogs, and stable performance even at high printing speeds.

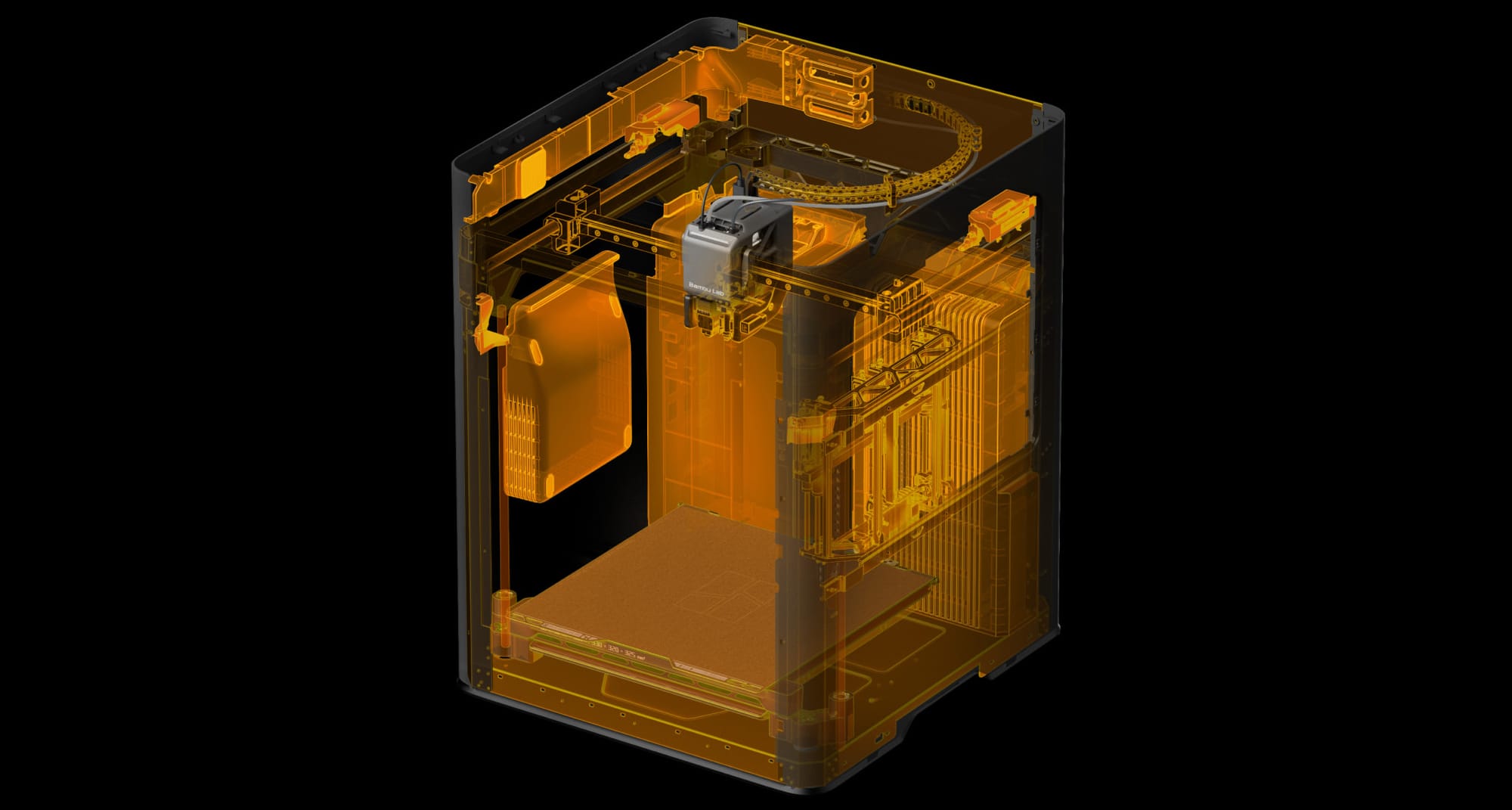

The H2C's chamber is constructed entirely with flame-retardant material, providing robust, passive fire safety protection across the entire enclosure.

Technical Specification:

- Build volume:

- Single nozzle printing: 305 x 320 x 325 mm

- Dual nozzle printing: 300 x 320 x 325 mm

- Total volume for two nozzles: 330 x 320 x 325 mm

- Maximum nozzle temperature: 350°C

- Default nozzle diameter: 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

- Built-in filament cutter

- Maximum heatbed temperature: 120°C

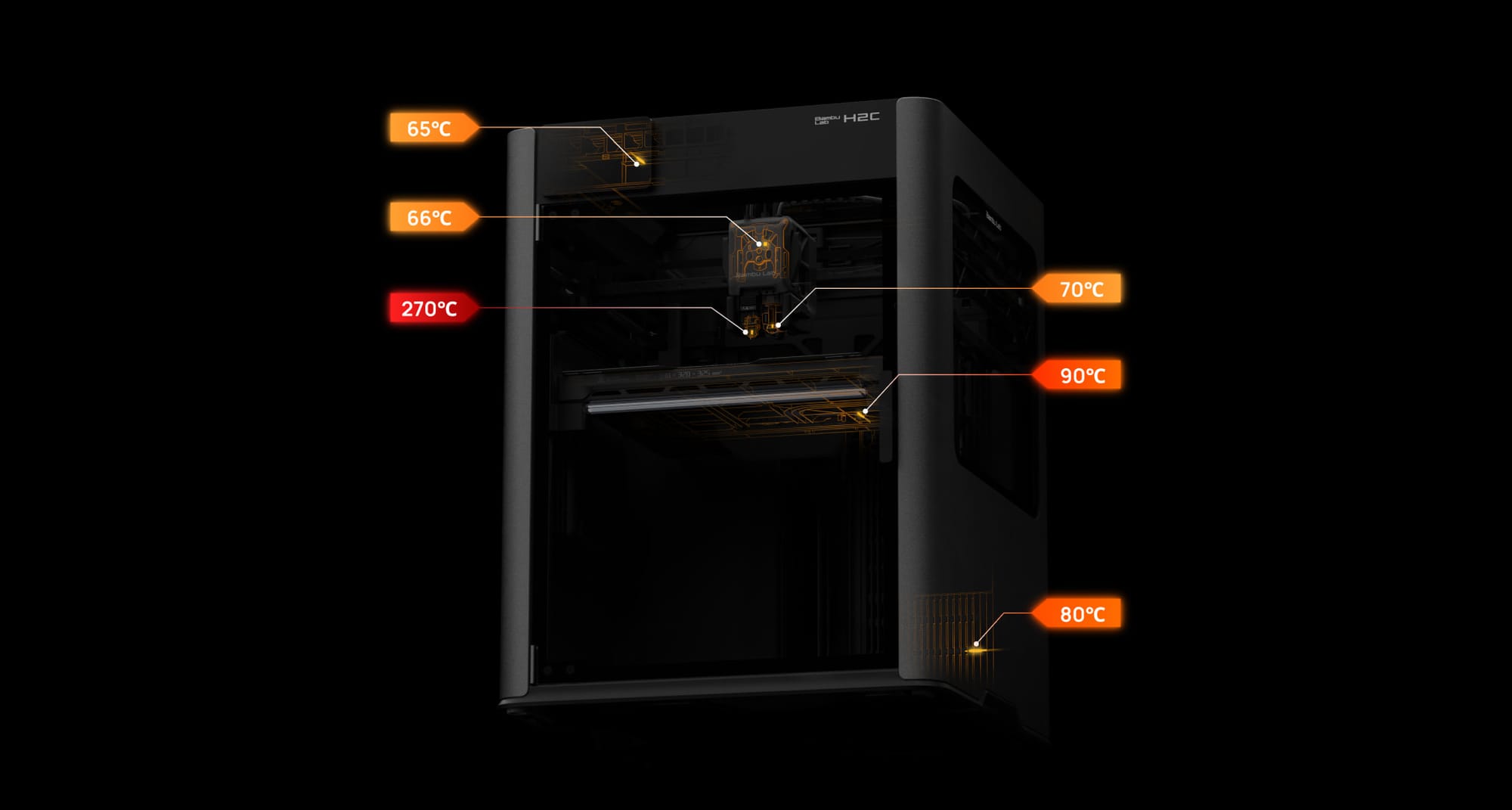

- Active chamber heating: 65°C

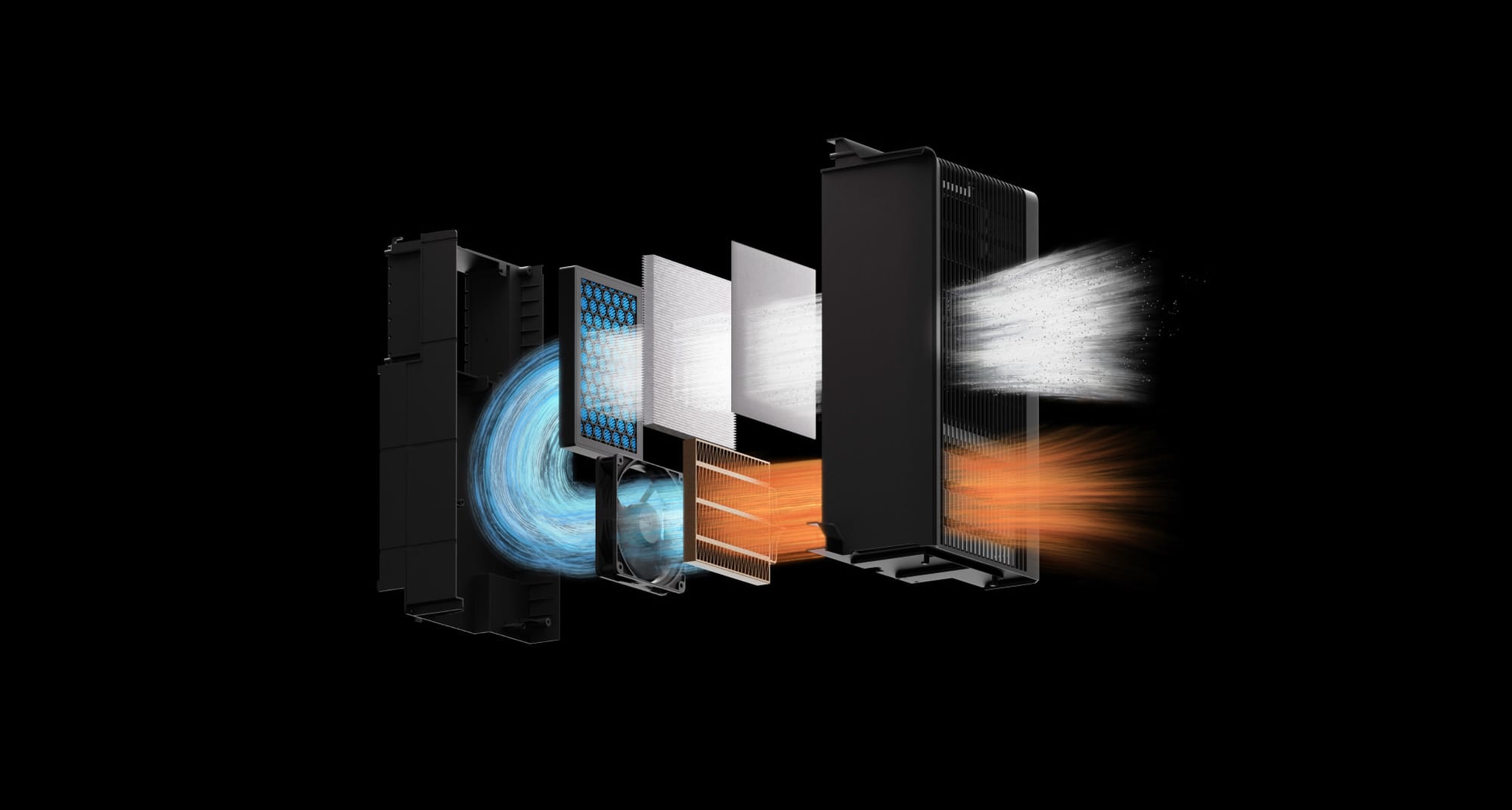

- Air purification system

- Cooling with closed loop control

- Sensors:

- Live View Camera: 1920 x 1080

- Nozzle Camera: 1920 x 1080

- BirdsEye Camera: 3264 x 2448

- Toolhead Camera: 1920 x 1080

- Door Sensor

- Filament Run Out Sensor

- Filament Tangle Sensor

- Filament Odometry

- Power Loss Recovery.

Final note

The H2C is designed for makers, engineers, designers, and professionals who demand industrial-grade reliability from a desktop machine. Its closed chamber, equipped with an adaptive airflow system, ensures stable conditions even when printing with high-temperature filaments, while an integrated filter maintains clean air in the workspace.

The H2C represents an entirely new concept of multi-material printing - one where every component, from inductive heating to contactless communication, has been engineered for precision, and automation.

This is the most advanced multi-material 3D printer on the market - combining the intelligence of industrial systems with the ease of use of desktop devices. Once again, Bambu Lab proves that reliability is what matters most, and that true innovation lies not only in creating new features but in ensuring that users no longer need to think about them.

Because everything simply works.