Bambu Lab Launches H2D to Rethink Personal Manufacturing

All-in-one personal manufacturing hub combines professional-grade 3D printing, laser engraving, cutting, and plotting in a single compact system.

MARCH 25, 2025 - Bambu Lab, a technology leader in desktop fabrication solutions, today announced the launch of its groundbreaking flagship product, the Bambu Lab H2D, setting a new standard in precision and performance.

"The H2D represents the culmination of our vision to fundamentally transform how designers, engineers, and makers approach personal manufacturing. We've built the H2D with the goal to excel at every capability it offers, eliminating the traditional 'jack of all trades, master of none' compromise that has plagued this product category." Dr. Tao, CEO at Bambu Lab

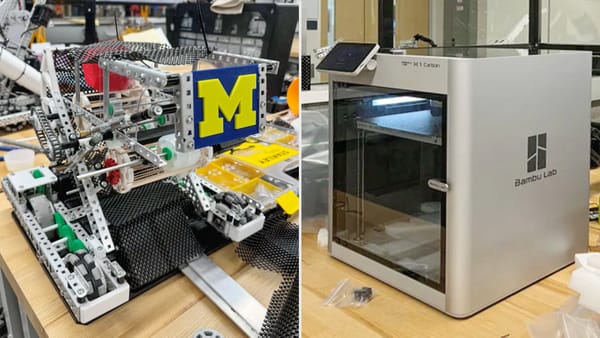

Rethink Personal Manufacturing

Imagine transforming a 3D-printed prototype into a finished product complete with laser-engraved details and precision-cut components—all on a single desktop device without compromising quality at any stage. This is the reality that the H2D delivers.

H2D is not a conventional 3D printer with added accessories. It's an entirely new category of product, built from the ground up to deliver exceptional performance across every function. Unlike typical all-in-one products that compromise quality for versatility, H2D excels at each capability it offers, making it the most versatile and powerful personal manufacturing system ever created.

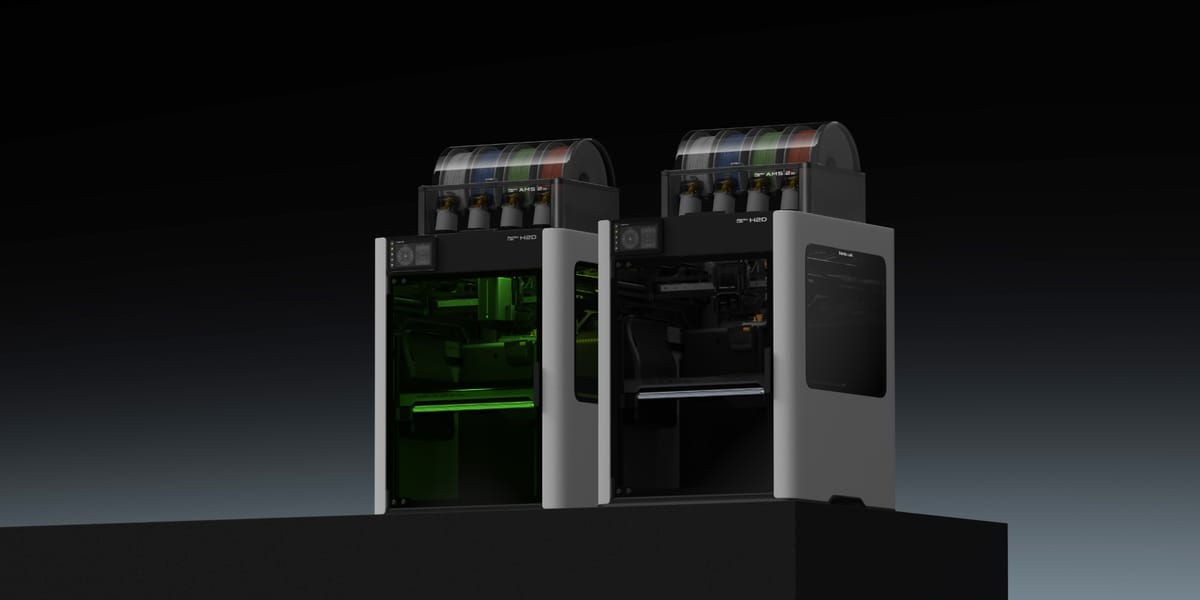

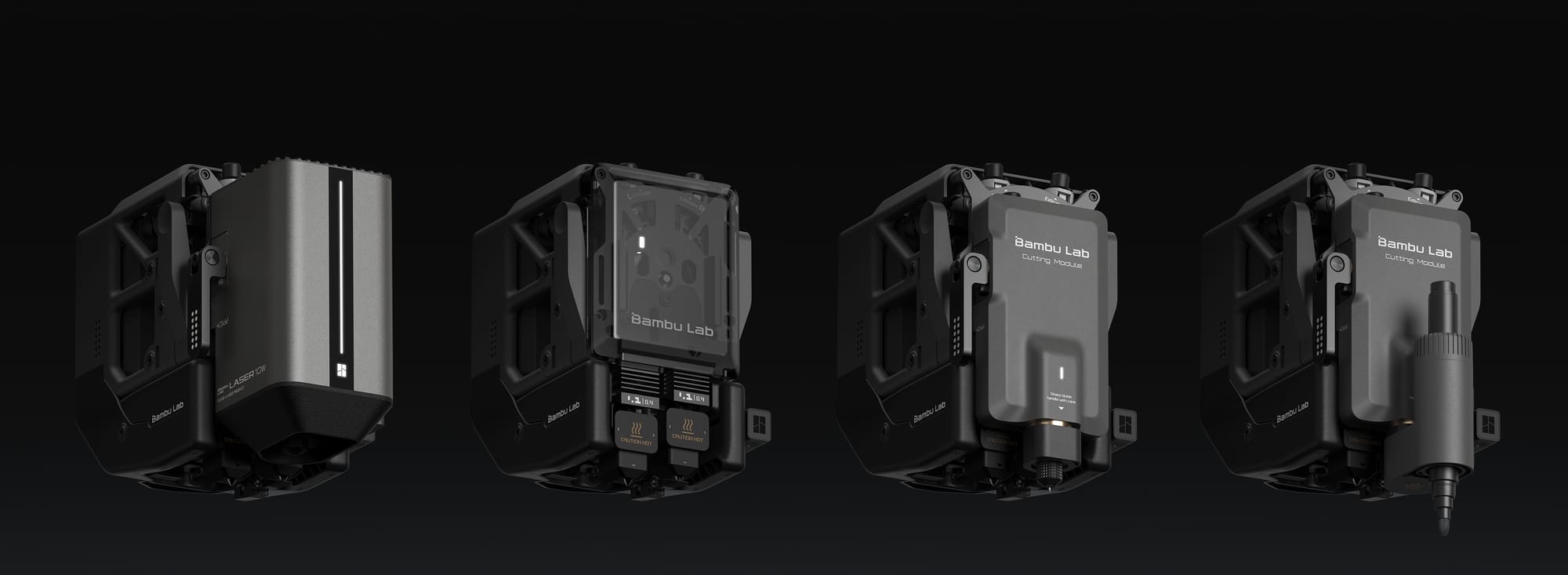

Comprehensive Manufacturing Capabilities

The H2D Laser Edition delivers professional-grade performance across multiple fabrication methods, with Live Spatial Alignment technology enabling seamless transitions between tools. Thanks to its BirdsEye and toolhead cameras, the system maintains up to 0.3 mm positioning accuracy to combine multiple processes in a single project.

- Advanced Dual-Nozzle 3D Printing: Features a 350°C hotend, expansive 350×320×325 mm³ build volume, 1000 mm/s max toolhead speed, and 65°C heated chamber for engineering-grade materials including carbon/glass fiber reinforced filaments.

- Precision Laser Engraving & Cutting: Incorporates an integrated air assist pump, vision-based alignment system, and comprehensive safety features including laser-safe windows, five flame sensors, AI camera fire detection, and emergency protocols.

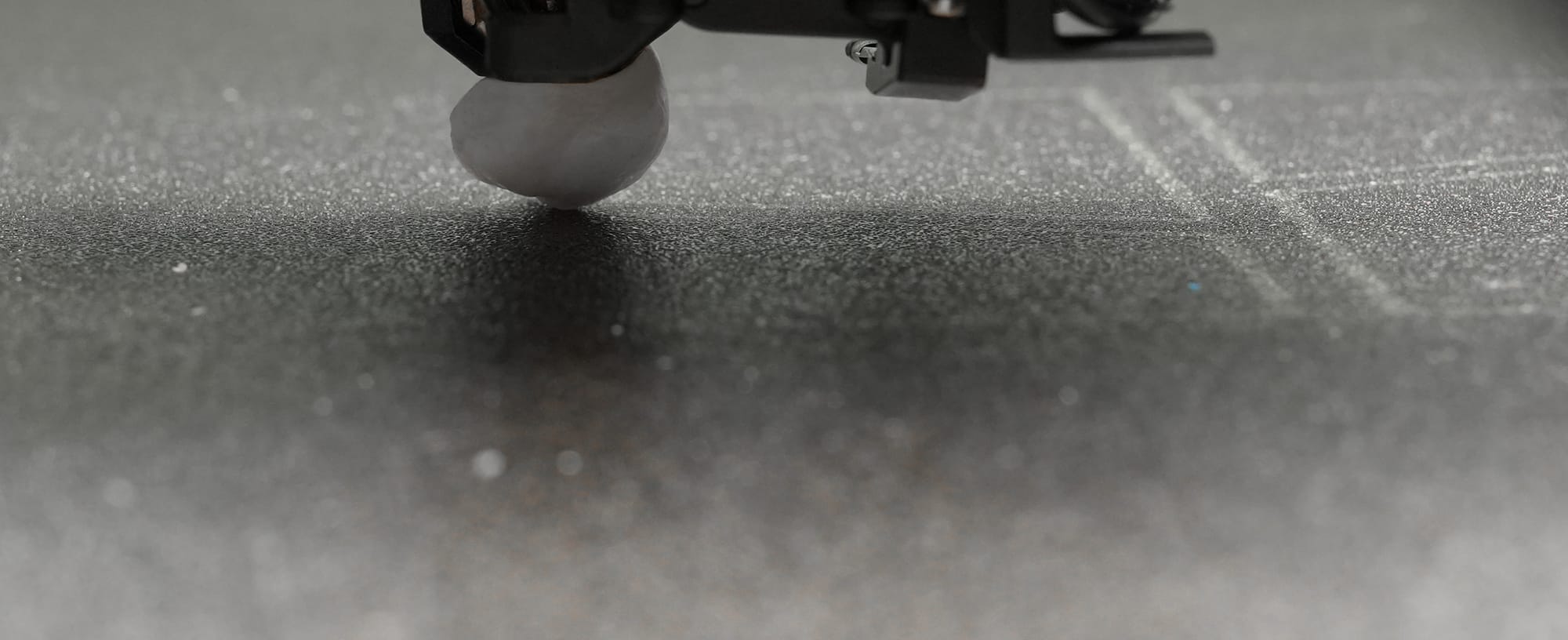

- Digital Cutting & Pen Drawing: Enables creation of precision vinyl cuts, custom stickers, and technical drawings with the same precision as dedicated machines.

Second Generation Technology

At the heart of H2D is a series of innovations that set new standards for precision and reliability:

Vision-Assisted Encoder System: Delivers exceptional 50µm motion accuracy across the entire build volume. A level of precision previously available only on industrial machines. This enables perfectly dimensioned parts for critical applications and seamless assembly of complex multi-part projects.

Vision-Assisted Encoder System

DynaSense Servo PMSM Extruder: Integrates a custom-designed permanent magnet brushless servo motor that precisely controls torque, speed, and position. This in-house technology enables real-time monitoring of extrusion pressure, automatic detection of partial nozzle clogs, and prevention of filament grinding, resulting in flawless surface quality even during high-speed printing.

DynaSense Servo PMSM Extruder

Eddy Current Nozzle Calibration: Proprietary dual-nozzle calibration technology that automatically handles X/Y offset calibration between dual nozzles, eliminating the labor-intensive calibration processes typically required by dual-nozzle systems. Delivers perfectly aligned multi-material prints with unprecedented ease and reliability.

Eddy Current Nozzle Calibration

Intelligent Nozzle Camera: An AI-backed macro lens camera that continuously monitors extrusion at the nozzle tip. Immediately detects material accumulation, filament deviations, and extrusion failures like nozzle clumping, air printing, and spaghetti.

SOTA Filament Monitoring: Industry-leading filament behavior control system, enables comprehensive material flow monitoring, throughout the AMS-to-nozzle path. With 15 strategically positioned sensors continuously tracking five key parameters: feeding velocity, tension, filament tip location, extruder thermal environment, and dynamic extrusion pressure.

Advanced Material Management

Complementing H2D is the redesigned Automatic Material System (AMS), now available in two specialized versions:

- AMS 2 Pro features a drying function and innovative electromagnetic vents that automatically switch between drying mode and storage mode, resolving the inherent conflict between effective filament drying and long-term storage.

- AMS HT, designed specifically for engineering filaments, can dry filament up to 85°C and incorporates a Filament Bypass Path that reduces feed resistance for fiber-reinforced rigid filaments and soft TPU.

Pricing and Availability

The H2D comes in multiple configurations to suit different user needs:

- H2D – Designed for users seeking advanced 3D printing capabilities with larger build volume, higher accuracy and speed, and multi-material printing capabilities. Includes build plate, spool holder, and accessory box. Available starting June 2025. MSRP: $1,899 USD.

- H2D AMS Combo – Adds the AMS 2 Pro for enhanced material management capabilities. Includes AMS 2 Pro, build plate, spool holder, and accessory box. In stock and ready to order starting March 25, 2025. MSRP: $2,199 USD.

- H2D Laser Full Combo (10W) – Built for makers who want to go beyond 3D printing and integrate additional manufacturing capabilities. Includes AMS 2 Pro, build plate, spool holder, accessory box, 10W laser module, cutting module, laser platform, cutting platform, and emergency stop button. Available for pre-order starting March 25, 2025, with shipping end of April. MSRP: $2,799 USD.

- H2D Laser Full Combo (40W) – The most comprehensive configuration for maximum manufacturing versatility. Includes AMS 2 Pro, build plate, spool holder, accessory box, 40W laser module, cutting module, laser platform, cutting platform, and emergency stop button. Available for pre-order starting March 25, 2025, with shipping end of April. MSRP: $3,499 USD.

While H2D delivers extraordinary capabilities, its feature-rich nature means it's best suited for users with some prior experience in digital fabrication or for those willing to invest time in learning these advanced tools to get the most out of what the machine can do.

All configurations will be available in our store and select retailers. For more information, including specifications, materials, and accessories, visit www.bambulab.com/h2d.

#RethinkPersonalManufacturing