Eaton scales industrial manufacturing with Bambu Lab's 3D printing technology

How global manufacturing leader gained flexibility, speed, and tangible savings

The events of 2020 - 2022 (global pandemic and war in Ukraine) forced the industrial manufacturing sector to adopt an entirely new approach to managing its resources. Companies find themselves at a turning point where traditional production methods are being replaced by more flexible, digital, and decentralized solutions.

Growing pressure to shorten lead times, reduce costs, and strengthen supply chain resilience is driving enterprises worldwide to seek technologies that allow them to respond faster and operate closer to real, day-to-day operational needs.

One of the key elements of this transformation is a shift in how auxiliary components, tooling, and spare parts are produced. For decades, these areas were dependent on external suppliers, long procurement cycles, and high unit costs—particularly for low-volume production.

Such an approach, however, limits flexibility and slows response to unforeseen events such as equipment failures, design changes, or the ergonomic needs of workers.

3D printing technology has long appeared to be an obvious solution.

Yet, its adoption was often hindered either by the high cost of machines and consumables or by the shortcomings of cheaper alternatives - frequent failures, poor part quality, and still relatively long single-part production times.

This began to change after 2022, following Bambu Lab’s market debut.

The X1 models, followed by the P1P and P1S, permanently reshaped how 3D printing is perceived in a production context.

What proved critical was not only the technological capability itself, but also ease of implementation, consistency of results, and the ability to scale without excessive capital investment.

These are the factors that determine whether a solution becomes permanently embedded in everyday production or remains merely a curiosity used on an occasional basis.

Interestingly, as 3D printing is adopted within manufacturing companies, organizational culture is evolving as well. Businesses are discovering the value of enabling production teams to solve problems independently and experiment with new tools.

Shortening the path from idea to physical solution translates not only into financial savings, but also into higher employee engagement and improved workplace safety.

Large, global organizations have managed to translate these broad trends into concrete, measurable changes in their operations.

One such example is Eaton - a company that has effectively aligned production needs with a modern approach to additive manufacturing, creating a solid foundation for continued growth.

Eaton Corporation

Eaton is a global leader in power management solutions, operates across a diverse range of industries including electrical, aerospace, and mechanical systems. With operations in over 175 countries, the company continually seeks technologies that improve efficiency, safety, and scalability within its manufacturing processes.

Additive manufacturing has long held potential for Eaton, particularly for producing custom tooling, fixtures, and low-volume replacement parts.

However, challenges with capital investment, inconsistent user experience, and a fragmented printer infrastructure had stalled broader adoption.

That changed when Eaton standardized on Bambu Lab’s X1E printers...

The Challenge: complexity and lack of intuitiveness and standardization

Prior to adopting Bambu Lab’s solutions, Eaton’s additive manufacturing footprint was both limited and inefficient.

The company had deployed 193 polymer printers across 47% of its factories, but these included 72 different makes and models.

This diverse mix created significant complexity in training, maintenance, and workflow standardization. More critically, many of the existing printers were not intuitive enough for widespread use on factory floors.

Capital cost was another major barrier. For many Eaton sites, the perceived risk of investing in AM outweighed the potential benefits. Compounding this issue was the operational reality - engineers and technicians often lacked the time or expertise to troubleshoot finicky hardware and software setups.

The Solution: Bambu Lab X1E

Eaton turned to Bambu Lab and adopted the X1E printer across its operations. The decision was driven by several key factors:

- industrial design: the X1E is equipped with an ethernet port for enterprise connectivity, and also helps ensure data security; it also has a temperature-controlled chamber that allows for safer, more reliable printing,

- ease of use: unlike many alternatives, Bambu Lab 3D printers required minimal setup and configuration, making them suitable for factory environments where simplicity and uptime are essential,

- low cost of entry: the affordability of the Bambu Lab solution made it easier for Eaton to scale adoption across multiple sites without significant capital expenditure.

Values brought by Bambu Lab

The adoption of Bambu Lab printers has had a measurable impact on Eaton’s manufacturing operations:

- expanded adoption: in just two years, the company increased its 3D printer count to over 300 units across 70% of its factories - nearly doubling the footprint while significantly reducing platform fragmentation,

- reduced costs: Eaton reports a more than 10x reduction in AM costs compared to prior printers,

- improved lead times: the speed of the Bambu Lab printers has allowed Eaton to produce parts such as jigs and tooling within the same day - cutting turnaround times by more than half!

- streamlined workflow: the ease of use has removed traditional barriers to entry, enabling factory teams to create and deploy parts on-demand with minimal training.

Applications

Eaton primarily uses Bambu Lab printers for on-the-floor operational support. Here is part of Bambu Lab 3D printer applications:

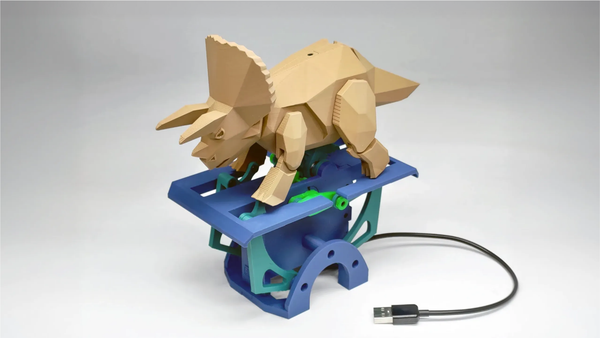

Tooling and Fixtures

Custom drill guides - which are made in just 3 hours - help to achieve accurate drilling of difficult to machine holes on the corner of the housing.

Weld alignment tools act as quick alignment guide to consistently align tubes for welding.

3D-printed caps for aluminum Vblocks protect the parts and avoid scratches/damage.

Spare and legacy parts

Producing small plastic components like inserts and caps in-house eliminates long lead times and minimum order requirements. In fact, these inserts take just 10 minutes to print.

Before Eaton adopted 3D printing, these plastic caps were typically made of metal. Producing them from metal required specialized tooling and made bending difficult. In the past, it took 3 days to manufacture this part, but with a Bambu Lab 3D printer, that time has been slashed to just 23 minutes!

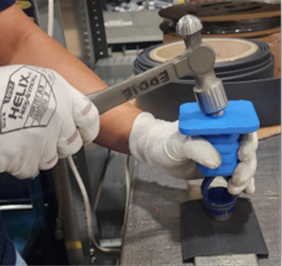

Safety enhancements

Components such as rivet guides and hand guards significantly enhance worker safety during manual operations. The rivet guide, for instance, secures the rivet in place while keeping the operator's fingers out of the line of fire during manual hammering.

3D-printed hammer guards protect against hand injuries during manual mushrooming operations. Furthermore, the ability to work with advanced materials - such as PPS-CF - has significantly expanded Eaton’s use cases, enabling the production of parts that require superior heat resistance and mechanical strength.

Future outlook

Eaton’s experience with Bambu Lab illustrates how a well-designed, accessible AM solution can dramatically accelerate adoption - even in complex, distributed manufacturing environments.

By addressing core barriers around cost, usability, and reliability, Bambu Lab has enabled Eaton to transform additive manufacturing from a niche capability into a scalable, everyday tool on the factory floor.

The company continues to expand its infrastructure by leveraging the full potential of 3D printing technology.