Expanding 3D Printing Access at Manchester Community College

At Manchester Community College and Spark Academy, students aren’t just learning about manufacturing, they’re doing it.

Reliable access to 3D printing can make all the difference in a manufacturing and design program. At MCC and Spark Academy, outdated equipment made it difficult for students to complete their projects. Upgrading to Bambu Lab printers changed that.

“The speed and accuracy of the Bambu printers let me assign more individualized projects to my Solidworks design students. Our older 3D printers created a bottleneck and not everyone could print their projects during the semester. Students now have time in class to iterate on their designs with direct access to the printers." – Dan Larochelle, Advanced Manufacturing and Robotics Department Chair

The Challenge: Smart, Safe, and Scalable 3D Printing

How do you prepare students for real-world careers in manufacturing, robotics, and STEM? At Manchester Community College (MCC) and Spark Academy, the answer is hands-on experience.

To take their training to the next level, they needed a scalable, high-performance 3D printing setup. One that could serve both classroom learning, for programs like Advanced Manufacturing Technology, and full-scale production, to mass-produce XRP robots for FIRST Global Challenge and other STEM initiatives.

The challenge? They had multiple non-negotiable requirements: the setup had to be safe for students, cost-effective for the school, and efficient enough to manage multiple printers across two locations– without sacrificing performance.

With these goals in mind, MCC and Spark Academy searched for a solution that could handle it all.

The Solution: Two Setups for Two Needs

After evaluating their options, MCC and Spark Academy implemented a customized two-printer setup to meet both classroom and production needs.

1. A Smarter, Safer Teaching Lab

The first-floor lab was equipped with 8 Bambu Lab X1E 3D printers, chosen for their:

- HEPA filtration to remove 99.99% of harmful emissions.

- Enclosed build for added safety and temperature control.

- Multi-material printing with AMS compatibility, supporting complex projects.

- Wired and wireless network options for flexible classroom management.

These printers became an essential part of the Advanced Manufacturing Technology (AMT) program, where students gain hands-on experience in engineering design, solid modeling, and additive manufacturing principles.

They learn how to translate digital concepts into physical parts, exploring the impact of slicing, support structures, and material choices on production. By working directly with 3D printers, they also develop a deeper understanding of manufacturing workflows and how design decisions affect the final product.

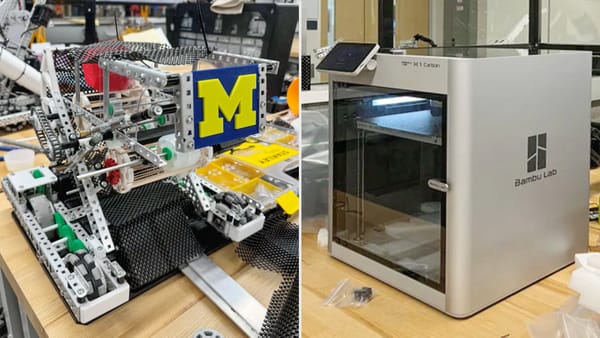

MCC’s 3D printer equipped classroom.

Instructors also benefit from group control features, which enhance classroom efficiency by allowing multiple printers to be managed simultaneously.

For research projects requiring confidentiality, the X1E’s physical network switch provides an extra layer of security. By disconnecting network access at the hardware level, it ensures that sensitive print files remain protected from unauthorized access.

With traditional manufacturing, students designed mechanical parts but rarely got to produce them. Now, they can print their models within a single class, reinforcing theory with hands-on practice.

2. Scaling Production with a Print Farm

The second-floor print farm is all about production. Spark Academy deployed 24 Bambu Lab P1P printers, chosen for their high-speed core XY performance and group control features, which make managing multiple machines seamless. While the P1P lacks an enclosed build, it is perfect for fast, consistent PLA printing, ideal for producing at scale.

This farm is dedicated to producing XRP robots, which are used in global STEM programs. With a steady output, Spark Academy has printed over 2,200 XRP robots, providing students with real-world manufacturing experience.

Spark Academy uses its print farm to produce XRP robot kits like these.

Note: If you’re interested in experimenting with an XRP robot, you can purchase a kit from Sparkfun.

The Results: More Hands-On Learning, Greater Impact

The introduction of Bambu Lab printers transformed MCC and Spark Academy’s approach to education:

- More students get hands-on experience: With eight classroom printers instead of just one, students no longer have to wait an entire semester to see their designs materialize.

- Faster production for STEM outreach: Spark Academy’s print farm has produced thousands of robots, engaging students in both design and manufacturing.

- A direct link to industry workflows: MCC’s curriculum now mirrors real-world applications and workflows, with students gaining practical knowledge from designing to prototyping and manufacturing.

Looking forward, MCC and Spark Academy will continue to explore ways to integrate 3D printing into their programs, from robotics competitions to engineering projects.

At Bambu Lab, we’re proud to support journeys like these that are making learning more hands-on, accessible, and fun!

Do you use 3D printers at your school or university? We'd love to hear your story– tag us on social media @BambuLab.