How a Local 3D Printing Shop Led a Nationwide Disaster Relief After Hurricane Helene

Beverly Tan and a nationwide network of makers used ingenuity and 3D printing to restore hope, connectivity, and resources to North Carolina communities.

When Hurricane Helene devastated North Carolina, it left communities without power, water, and basic infrastructure. Beverly Tan, owner of Ecovate 3D in Raleigh, felt compelled to act, given her personal ties to the hardest-hit areas. What began as a few emails asking, 'Can you 3D print this?' rapidly grew into a large-scale relief effort that united makers from across the country.

“Our little 700-square-foot shop became a disaster relief center. It was amazing to see everyone come together to help.” – Beverly Tan, owner of Ecovate 3D

Makers to the Rescue

In the aftermath of Hurricane Helene, emergency responders faced overwhelming challenges. Mudslides blocked roads, entire neighborhoods were cut off from communication, and the lack of potable drinking water made basic survival an uphill battle. With resources stretched thin, there was an urgent need for innovative, community-driven solutions.

Photos taken in Asheville after the hurricane, by Andrew Dodson.

Eager to help, Beverly partnered with Operation Connect Carolina and the Raleigh Mutual Aid Hub, two networks coordinating disaster relief efforts, and the Asheville Tool Library, a volunteer-powered nonprofit that shares tools and provides community education. She also put out a call on Facebook, inviting volunteers with 3D printers or CAD expertise to join the effort.

The response was overwhelming. Makers from Utah, New York, and beyond connected via Discord, forming a decentralized manufacturing network. From Beverly’s shop in Raleigh to individual printers across the country, a shared mission drove the effort. Teenagers printed after school, hobbyists ran machines late into the night, and volunteers worked around the clock to meet critical needs.

Among the many volunteers, teenagers from local schools stood out, eager to make a difference even if they couldn’t be on the ground. With Beverly’s team, they found other ways to make a difference through 3D printing.

“It was great for these kids to see how they could help without being on the ground,” Beverly recalled. “Many didn’t realize the life-changing impact they had, bringing internet to over 100,000 people and getting water to those in need, all through makerspaces mailing in solutions.”

Hobbyists, teachers, and students alike contributed countless hours of printing time to help local communities start to bounce back.

Restoring Internet Access and Clean Drinking Water in Disaster Zones

With the network of makers in place, the team began addressing urgent challenges on the ground. One of the first priorities was restoring internet access in disaster zones, where it’s critical for coordinating rescue efforts, accessing emergency services, and allowing families to communicate and connect with loved ones.

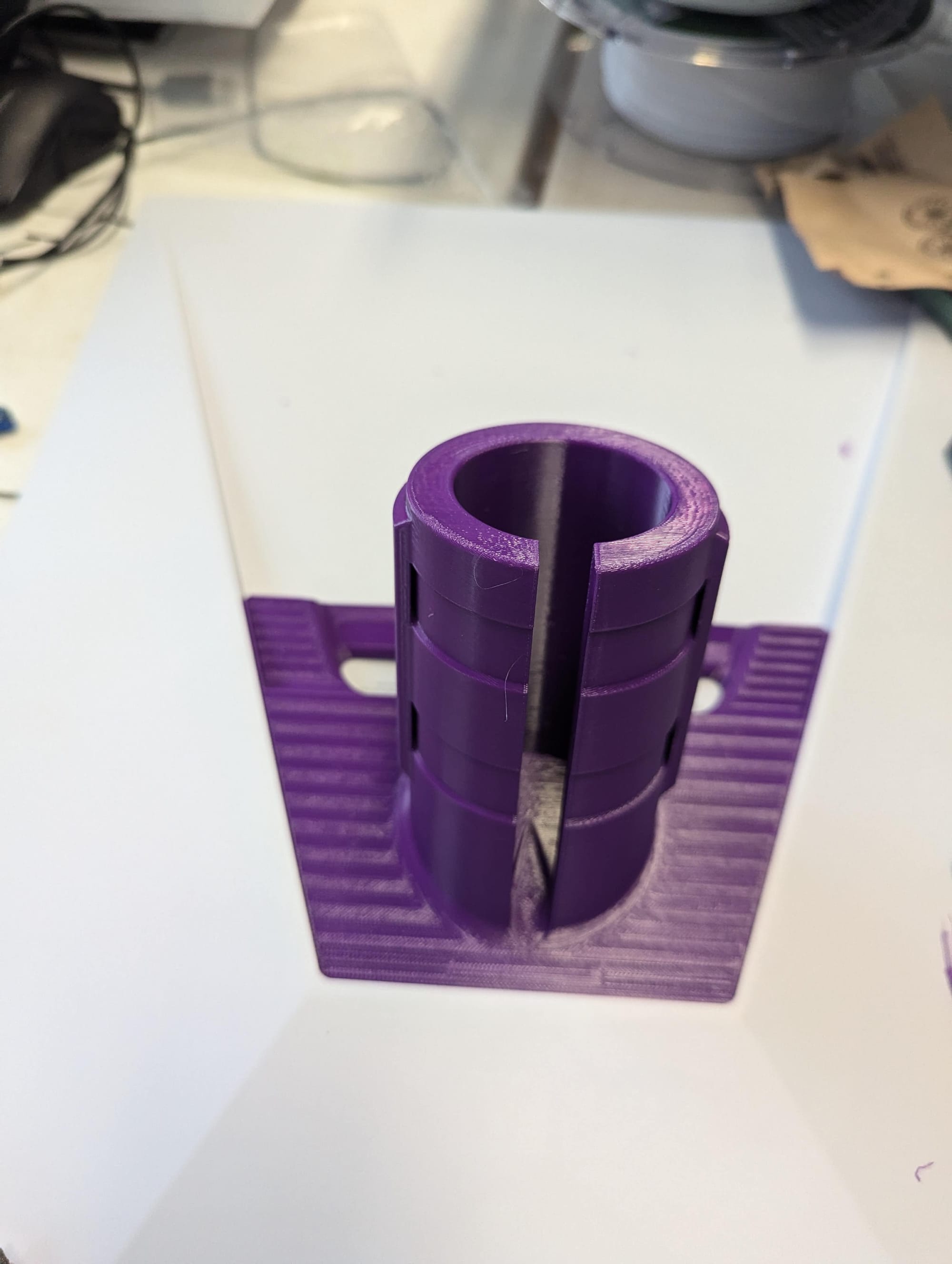

Left: A determined Beverly Tan. Middle: Prototyping the Starlink adapters. Right: The final Starlink adapter for telescopic pole.

“We had to figure out a way to raise the antennas high enough to function without rooftops, so we came up with a design that could be mounted on telescoping poles stuck in buckets of concrete,” Beverly explained.

These raised antennas restored internet to over 100,000 people, providing a vital communication lifeline.

Another pressing need was clean drinking water. Firefighter hoses, often used to transport water, were unsuitable because they contaminated the supply. Working with volunteers, Beverly’s team reverse-engineered and 3D printed spigots for IBC tanks, making it possible to transfer potable water from large trucks to smaller containers safely.

“We had someone with an IBC tank on their farm reverse-engineer the spigot design and share it on Discord, and from there, dozens of makers pitched in to print them,” Beverly shared.

In one memorable moment, a 12-year-old volunteer on Discord solved a critical design flaw, ensuring the spigots functioned perfectly and enabling clean water delivery to thousands of people.

Left: A spigot and its adapter for the IBC tanks. Right: An Asheville Tool Library volunteer on-site with the adapters in action.

While many efforts focused on critical infrastructure, others turned their attention to providing comfort. Volunteers with PLA-only printers stepped in to create lightweight, non-essential items, such as fidget toys for children who had lost everything and toothbrush covers for people in shelters. “These kids lost so much, and even something small like a fidget toy could make a difference,” Beverly said. Their thoughtful contributions showed how even small gestures can have a big impact in times of crisis.

Each of these innovative solutions tackled a specific gap in the disaster response effort.

Community prints ready to leave Beverly’s shop.

Creating a Blueprint for Future Relief

While the relief effort came together beautifully thanks to everyone’s determination, Beverly sees room to improve preparedness for future disasters. She envisions a system where 3D printing can be mobilized even faster:

- A cloud-based library of ready-to-print designs for common disaster needs.

- A pre-organized volunteer network of makers, schools, and engineers.

- Communication channels like Discord to coordinate efforts in real time.

She also highlights the unique advantages of 3D printing. Unlike stockpiling supplies that may go unused, 3D printing allows on-demand manufacturing tailored to the specific needs of each disaster. “It’s easier to have 3D printers than to store pallets of products,” she says.

As the recovery from Hurricane Helene continues, Beverly hopes her story inspires other makers to explore how their talents can serve their communities. Her takeaway is clear: “You can help people with your hobbies and skillset. 3D printing isn’t just about making things. It’s about solving problems, creating connections, and empowering others to do the same.”

Feeling inspired by this story? Visit Beverly's store, Ecovate 3D, at 14 Glenwood Ave, Raleigh, NC 27603, USA, to learn more, share ideas, or just say hello. Stay connected with the latest innovations and community projects by following Ecovate 3D on Instagram @ecovate3d and Beverly's creative journey @beverlytanfilm.