How Much Does a 3D Printer Cost (2024 Guide)

How much does a 3D printer cost? Learn about 2024’s models from entry-level to professional-grade options for any upcoming projects.

The concept of 3D printers dates back to the 1980s, when engineers theorized that industrial parts could eventually be created with computers and additive manufacturing techniques.

While most people are familiar with standard printers that produce text and images, a 3D printer works differently. It extrudes filament onto a heated plate, gradually building a tangible object layer by layer.

3D printers offer a wide range of applications, from home crafts to large-scale manufacturing. Let's take a closer look at the costs of 3D printers in 2024.

Price Range of 3D Printers in the Market

Naturally, 3D printers were extremely expensive when they were first introduced. But, how much does a 3D printer cost today? It depends on the type of printer that suits your needs. Generally, there are three to five categories of 3D printers available today. Matching your project to the right printer is a great place to start.

Entry-Level 3D Printers

Entry-level 3D printers usually cost between $100 and $400. Some of these entry-level printers are sold as home-assembly kits that require some work before use.

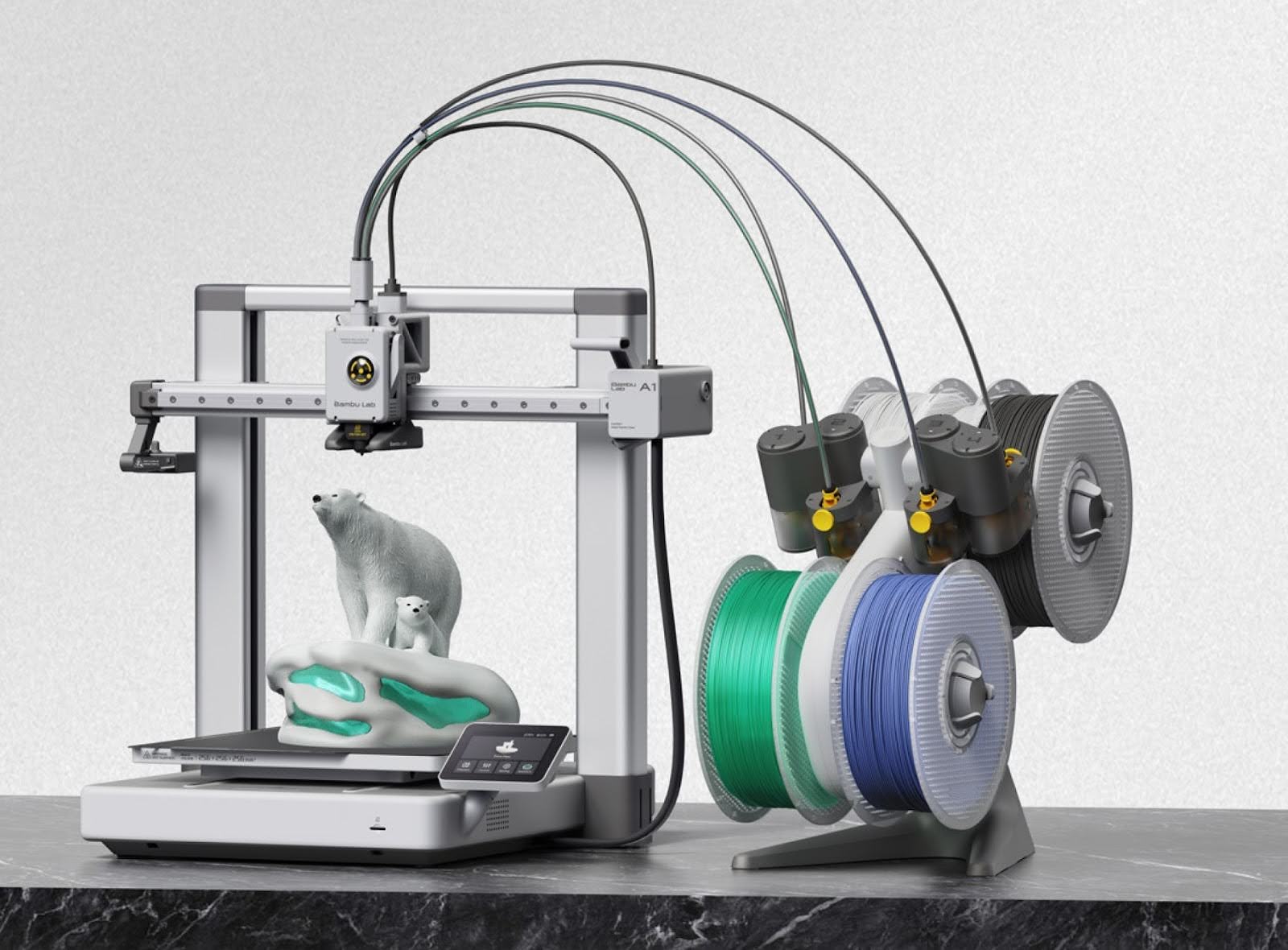

In the entry-level 3D printers section, Bambu Lab has the A1 series which includes the A1 mini and the A1. You might be wondering. How much does a 3D printer cost made by Bambu Lab? The answer is: not a lot!

The A1 mini is the cheapest 3D printer which is usually found for under $200 and can be used out of the box. In just 15 minutes, the printer can be set up and a print can be quickly started. If you are looking for a larger printer but a similar experience, the A1 can be had for less than $350 USD.

Both these printers can be equipped with the AMS lite system which gives the printer multi-color capabilities.

All the Bambu Lab printers are designed to allow anyone to experience 3D printing for the first time with ease, without complicated setup or manual calibration.

Hobbyist 3D Printers

Hobbyist 3D printers usually range from $400 to $1,000. These printers are designed for consumers who want to immerse themselves in this hobby. Depending on the model, these 3D printers can have tighter tolerances and print slightly larger objects than entry-level printers.

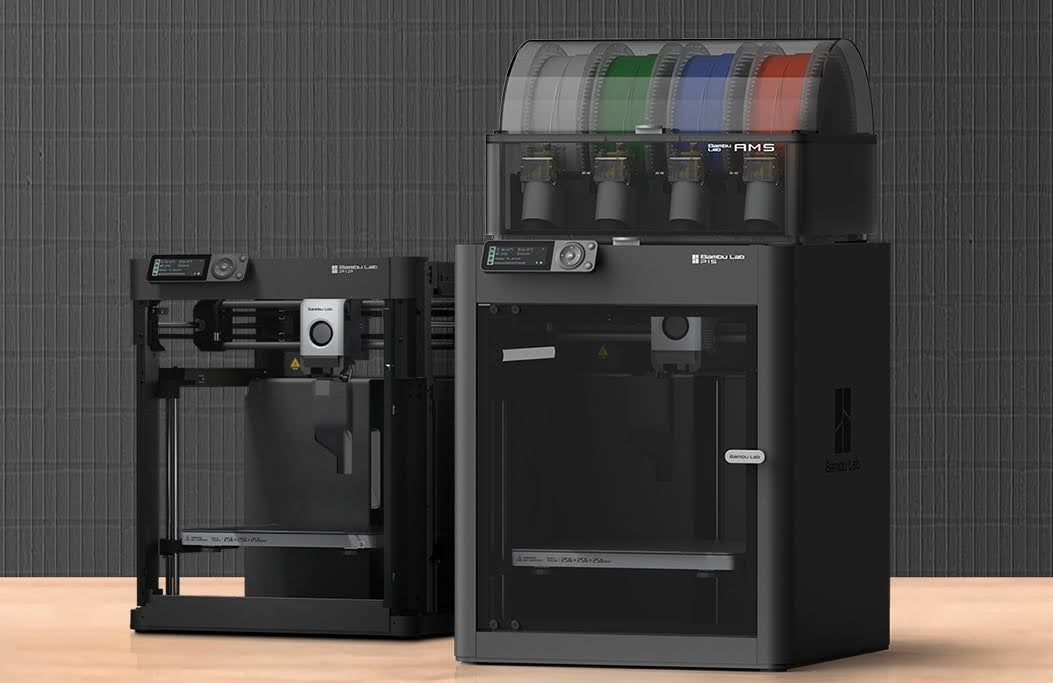

The Bambu Lab P1S 3D Printer is a top choice for hobbyists who seek both performance and versatility as it can print the most common materials on the market, and even technical filaments if they are upgraded.

One of the standout features of the P1S is its ease of setup and the relatively compact design.

The hardware and software are well-polished, ensuring a smooth user experience. The enclosed-body design is particularly beneficial for printing with high-temperature filaments, which is important for hobbyists. This expands the range of materials you can work with, allowing for more complex and durable prints.

For example, it is common for such a printer to use PETG, PC, ABS and ASA filaments to print various parts for different hobbies that require strong parts.

Lastly, the built-in camera (which is a feature present on all Bambu Lab printers) provides remote monitoring as well as the posibility to create timelapses of your prints. This is particularly useful for those who like to document their work.

Enthusiast and Prosumer 3D Printers

For 3D printing enthusiasts, you can expect to invest between $1,000 and $5,000 for a high-quality printer, and the price tag also brings more advanced printer features like auto-calibration of the filament, higher printing accuracy along the X, Y and Z axes and better build quality.

The Bambu Lab X1-Carbon is a printer capable of handling multi-color and multi-material printing with ease, thanks to its Automatic Material System (AMS). It features a high-speed CoreXY system with an acceleration of 20000 mm/s² for faster and more precise printing.

Using hardened parts, the X1C is also capable of printing abbrasive filaments like Carbon Fiber and Glass Fiber reinforced polymers lile PETG-CF, ABS-GF, ASA-CF, PA-CF and more. The vibration and extrusion compensation technologies ensure smooth and defect-free prints.

Anyone looking to seriously build objects multiple times a year, such as engineers, can greatly benefit from these 3D printers. Entrepreneurs who create products for online sales are also ideal candidates for these devices. Institutions might use a X1C for instruction, demonstrations, and other projects as well. With its flexibility to handle various filament materials and produce objects up to 12 inches in size, an enthusiast-level 3D printer like the X1C is a smart investment.

Professional and Industrial 3D Printers

Professional 3D printers, priced between $5,000 and $10,000, are distinguished by their advanced features, such as dual extrusion capabilities and the ability to handle large-scale builds. In this range, you can expect the machine to produce a high-quality prototype, even after a full weekend of printing.

The cost also reflects the machine's repeatability—once programmed, these printers can efficiently mass-produce objects for businesses or organizations. Additionally, many models can work with various filament types, including carbon fiber, ABS, and nylons. Professional 3D printers are ideal for small businesses and other groups looking to benefit from high-quality, reliable 3D printing.

How much does a 3D printer cost for industrial applications? Currently, industrial 3D printers cost $10,000 and up. Depending on the model, some 3D printers might have a six-figure price tag. Organizations will pay for the detailed accuracy and speed offered by these 3D printers. In addition, these printers can produce parts or objects much larger than hobbyist 3D printers. When companies purchase industrial 3D printers, their investment contributes to the business's overall profitability.

Industrial 3D printers offer precise tolerances, robust construction, and fast production times. However, they can come with certain limitations, such as contractual obligations with the manufacturer. Additionally, material costs may be higher, especially if the printer requires specific materials, such as metals or high-temperature polymers, that must be purchased directly from the manufacturer. Due to these constraints, most organizations outside of for-profit businesses may find it challenging to benefit from these high-end 3D printers.

Factors Influencing the Costs of 3D Printers

Several factors influence the overall cost of your 3D printer investment. One of the primary considerations is the quality of the printer's individual components which can include higher-end materials and finishes, for a long lasting use. Additionally, optional features, such as advanced cooling systems or vibration control, can drive up the cost but also enhance the printer's overall performance and print quality.

Second, another cost factor involves software and its user interface. With the latest software, your 3D printer can create intricate details that were difficult beforehand, and new software updates can bring new benefits to the end user a long time after the product has been purchased. Creating a functioning ecosystem and providing multiple feature updates to the software can increase the product's cost.

Finally, consider the indirect cost of electricity. A 3D printer often requires several hours to complete a build, and sometimes the process might even extend overnight. If you plan to use the printer for high volumes, investing in a faster, more expensive model upfront could be more cost-effective in the long run, as it would consume less electricity compared to a slower device. An enclosed 3D printer can use less power in its lifetime, as more heat will stay inside the printer compared to it being lost in the environment, leading to higher power consumption.

Is a 3D Printer Worth It?

A 3D printer can be a valuable investment if you plan to use it regularly for home projects or professional work. For hobbyists, the time and effort spent on each project bring a great deal of satisfaction, allowing you to create unique items like prototypes, tools, toys, or decorations by experimenting with the printer and filaments.

To ensure your investment is worthwhile, it's crucial to align your printing goals with the right 3D printer. For example, if you intend to produce high volumes of objects, consider a printer that's both reliable and it is part of a well-working ecosystem of software, hardware and consumables. It's also essential to familiarize yourself with the technology, maintain the printer properly, and understand its limitations. Doing so will ensure that your 3D printer meets your needs effectively for many years to come, making the investment both rewarding and cost-effective.

Conclusion

Each product has its own applications and limitations, from entry-level to industrial 3D printers. Before choosing a device, read and match the specifications to your needs. The 3D printer's value will be worth the investment. Check out the range of printers offered at Bambu Lab today!