Design, Print, Repeat: Josh’s DIY Adventure

"When I got my X1C, it was a mix of excitement and also, 'What did I just do?!' I hadn’t fully realized the reality of what I was getting myself into. I didn't consider MakerWorld or how things would change for me. Most of my thoughts at the time were, 'Life has been a struggle, this may not be the best use of my time, but it helps me get back to the things I love."

MakerWorld's got tons of designers, but Josh is the one who really stands out.

An Accidental Path to Creative Mastery

From the moment I first spoke with Josh, his passion for 3D printing was unmistakable. "I just want to bring the ideas in my head to life and turn my designs into real objects," he told me. Unlike many who carefully plan their way into the gaming industry, Josh’s journey was more of a happy accident. He began at an outsourcing company, thinking it was a temporary gig until something more aligned with his interests came along. But with the launch of consoles like the Xbox 360 and PS3, the gaming industry exploded with opportunities, and Josh quickly found himself hooked.

As a huge fan of the Fallout Series, working on the game was a dream come true. Josh designed the shotgun featured in the game, a project that holds a special place in his heart, even though the world has largely moved on from that version. "It was the first time I ever saw my work in a magazine," he said with a proud smile. Game Informer featured Fallout 3, and the character had Josh's hunting rifle slung over their shoulder.

During his time at Liquid Development (now part of Keywords Studio), Josh got the chance to work on big-name projects like Rock Band. As a newer artist, he was initially hesitant to take the lead when production challenges arose. But when Harmonix came in to talk about the game, Josh knew he couldn't let the opportunity slip by. He took charge, producing nearly half of the game’s iconic guitars and even overseeing the rest. One of the ones he worked on, the Telecaster, was so inspiring that after years of building digital models, Josh was driven to produce a physical guitar.

Some of the designs Josh worked on during his time at Liquid Development.

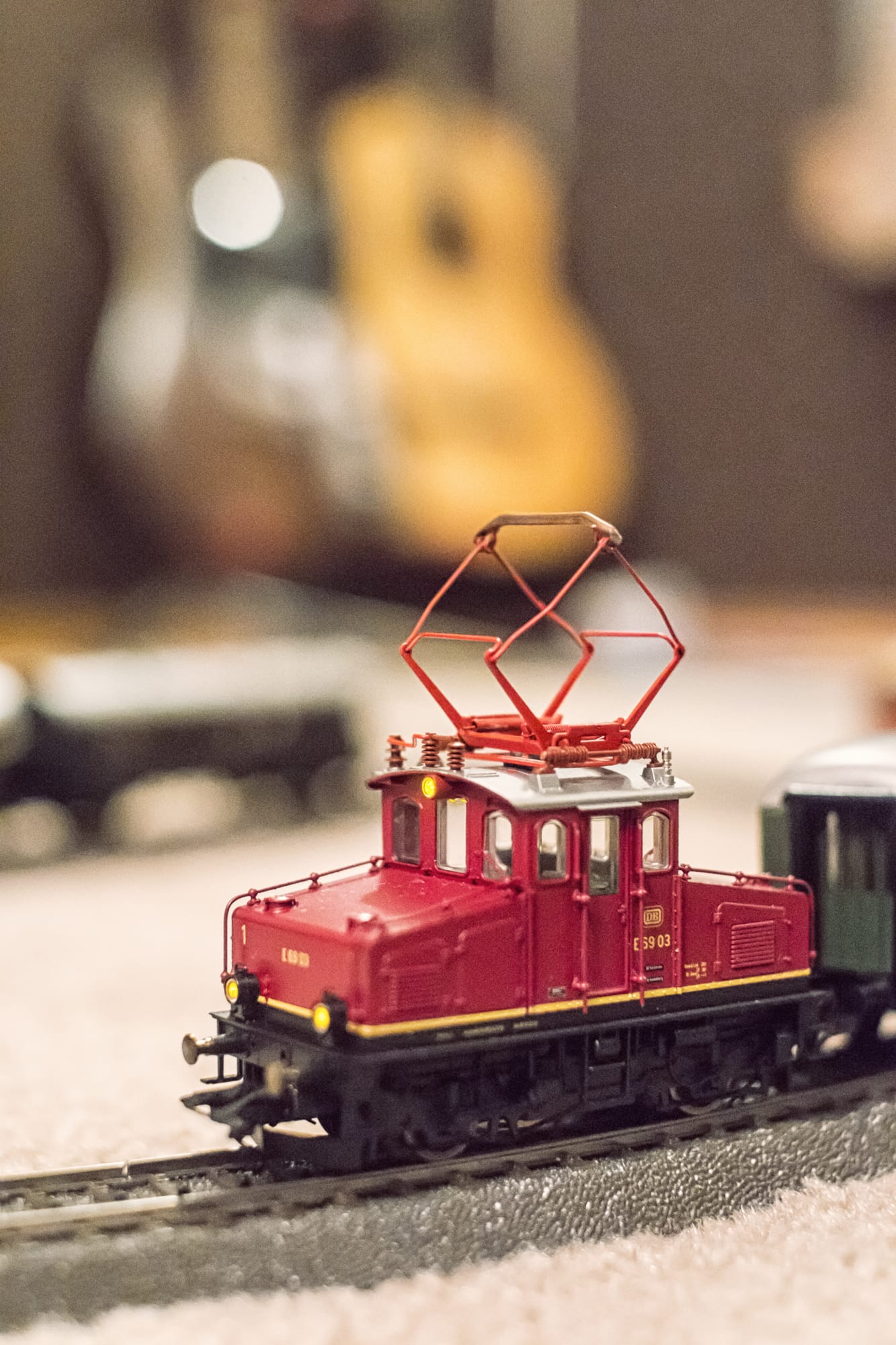

Our conversation then switched to hobbies, "I've always loved trains—it's one of my geekier hobbies," Josh admitted with a grin. He designed a raceable train for Forza Horizon 2 and worked on an overhead train for Borderlands 3. Before his 3D career, Josh had made a name for himself in the Trainz community, creating popular add-ons for the game. He believes 3D printing has massive potential in model trains, especially for buildings and scenery. However, he acknowledges that printing the trains themselves remains a more advanced challenge that only a few have mastered.

Trains are one of Josh's geekier hobbies. He used to design these trains.

"I think one of Joshes greatest strengths is that he is not only an absolute guru in all things 3D and 3D print related, but he’s also an accomplished artist as well. His years as an artist in the video game industry are an integral part of his 3D print designs and sets him apart from other designers. He has an expert grasp of real-world mechanics with an artistic eye." – Phil Blume, friend of Josh, work at a company that makes large models for store displays or trade shows, handling the sculpting part.

From Tinkering to Full-On Creating

While Josh is immersed in his gaming work, 3D printing has become part of his identity. "When I first got into 3D, I spent hours working with CAD, trying to recreate real-world objects," he said, leaning forward with enthusiasm. "But I got frustrated because I couldn't actually bring those designs to life, so I put the idea on hold." He paused, smiling at the memory. " Then I discovered 3D printing, and the spark reignited, everything just clicked "

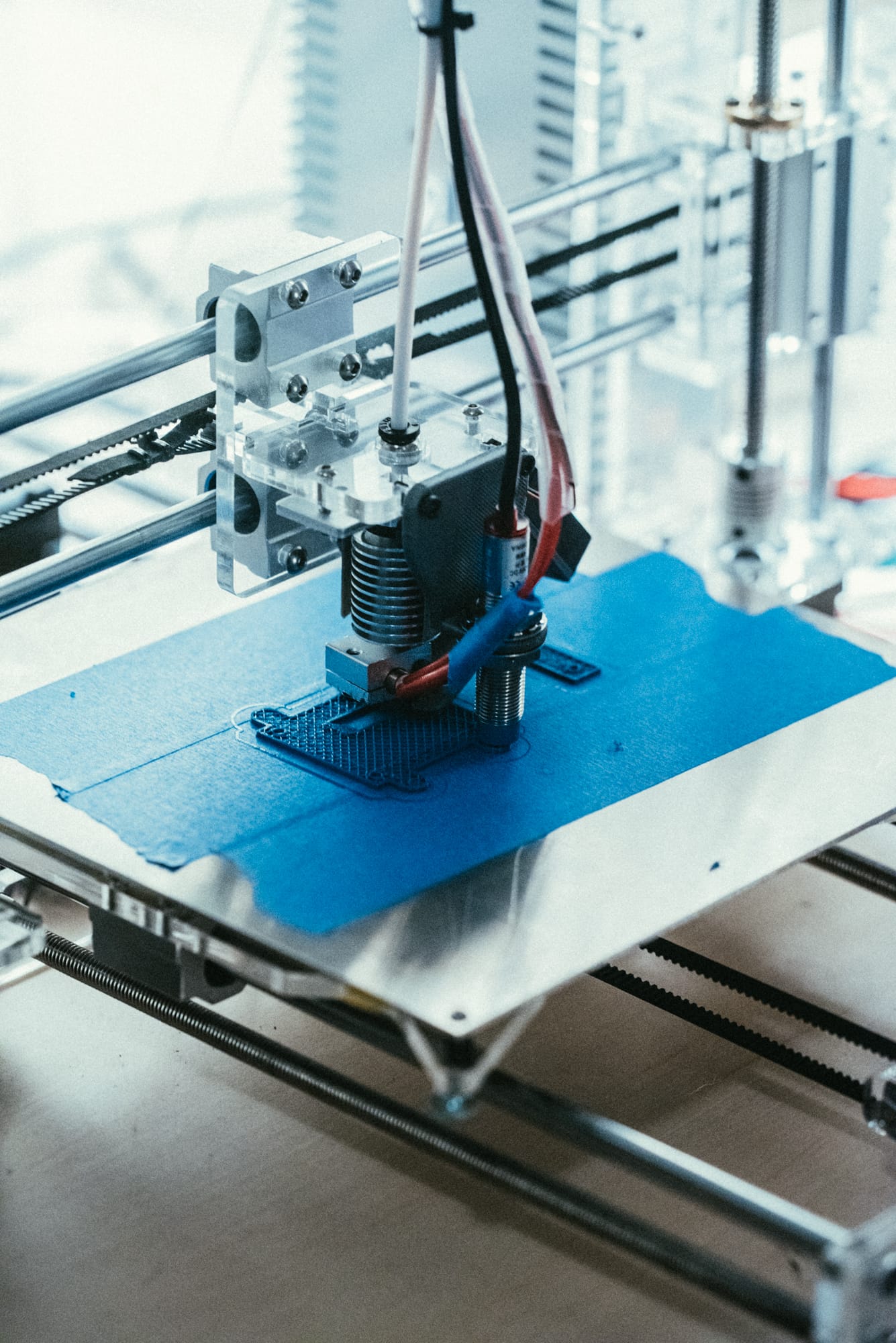

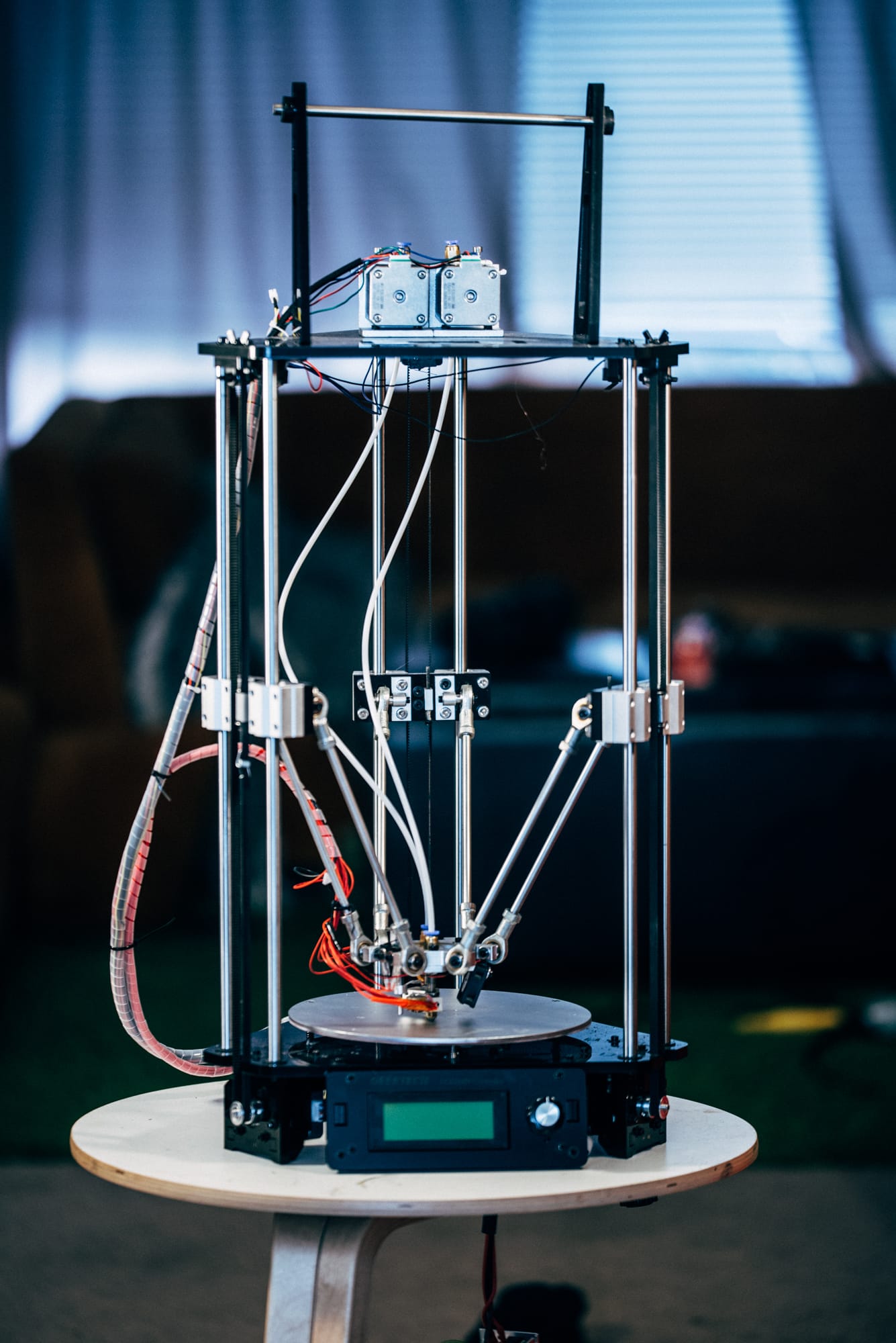

At the time, Josh only had limited access to CNC routers and metal mills, which severely limited what he could create. Things changed when he bought his first 3D printer, a Robo R1, just as affordable kits were gaining popularity. "Everyone told me it was a waste of time and the printers were junk, but I didn't listen. I bought the Robo R1 anyway," he recalled. "It had some cool features but definitely had its quirks. I spent more time fixing it than printing." Despite these early frustrations, 3D printing opened up endless possibilities, and Josh hasn't looked back since.

Josh's first 3D printer and the Hypercube he built himself.

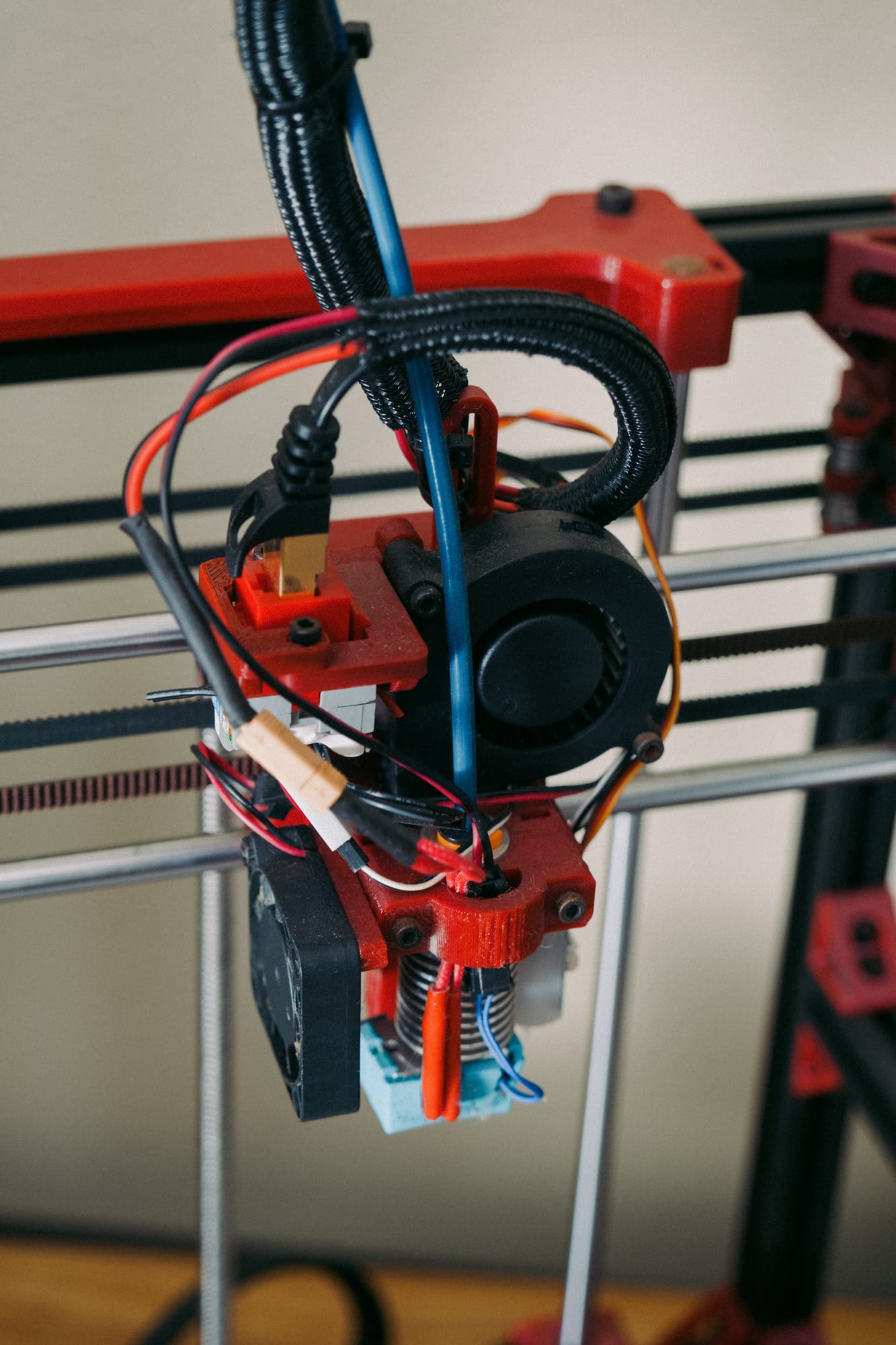

Josh's journey into 3D printing took a significant leap when he built his own Hypercube. But he didn't stop there. He made extensive modifications, transforming it into something totally his own. "It was awesome," Josh said with a grin. "It had all the latest features at the time. I even designed a custom UI for the touchscreen." Although he no longer uses the Hypercube, he keeps it stored away, because it's a part of him.

As he proudly pulls it out, Josh reflects on the years he spent designing custom hotend carriages for his printers. One of his most impressive designs featured a swappable hotend assembly, held in place by magnets for easy servicing. He even incorporated an Ethernet cable to quickly unplug the wires, a clever modification that streamlined the process. "I had both a standard E3D hotend and an E3D Volcano hotend," Josh explained. "Swapping the whole assembly was actually easier than changing a nozzle on the X1 or P1," he added with a laugh. "The only drawback? I had to reupload the firmware every time I switched nozzles," Josh admitted, though this technical hurdle didn't diminish the pride he took in the innovation behind his design.

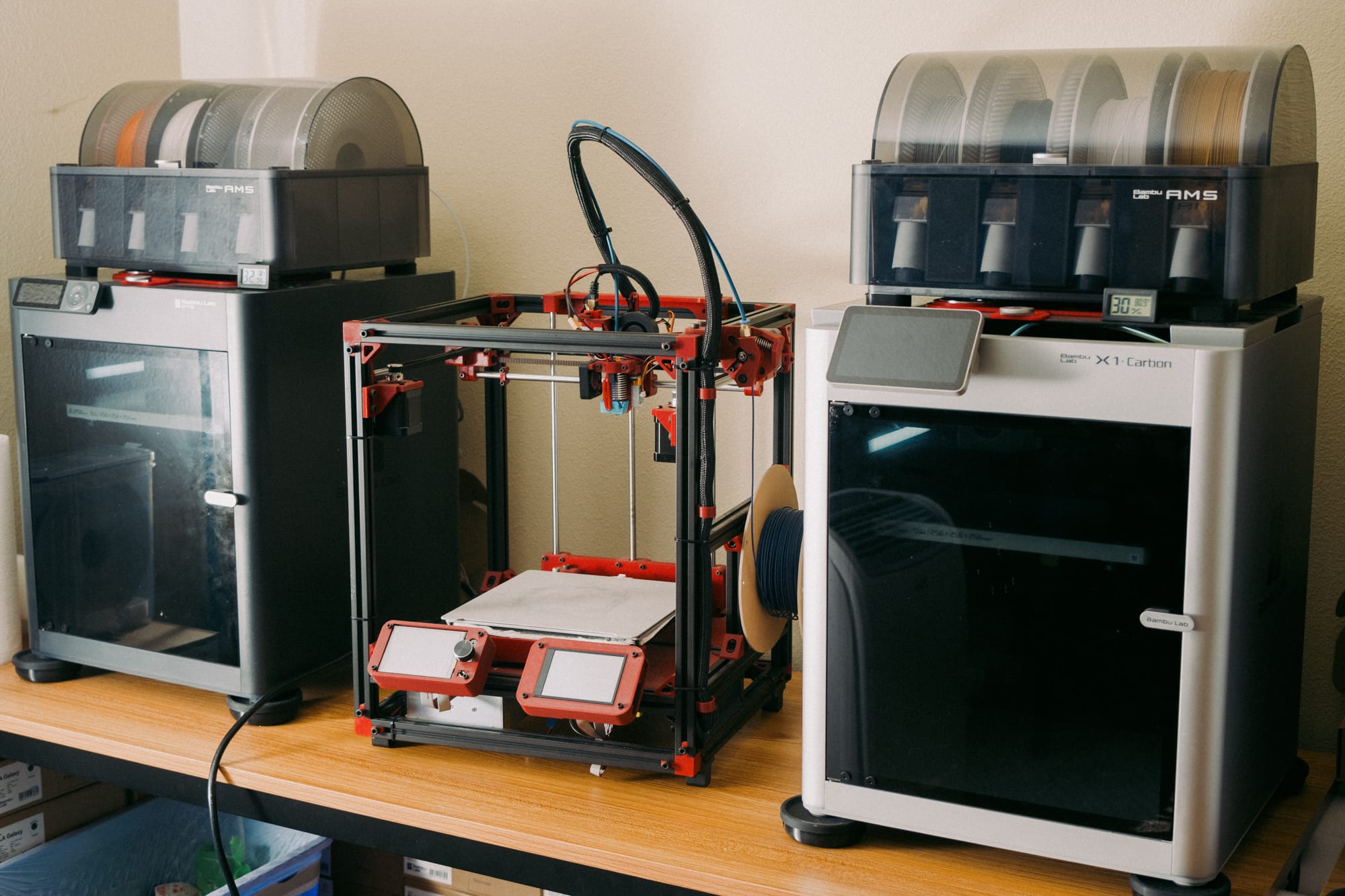

Still, the technical challenges of building printers from scratch took their toll. "I didn’t want to keep messing with all the technical stuff or feel like I had to build a printer from scratch just to get good quality," he admitted. This realization led him to the Bambu X1C, a printer that transformed his creative process. " The seamless integration between hardware and software let me focus completely on designing." His first project with the X1C, a 3D-printed R/C vehicle kit, reignited his passion for larger, more complex builds. " That project helped me get a real feel for the X1C and set the stage for everything that came after."

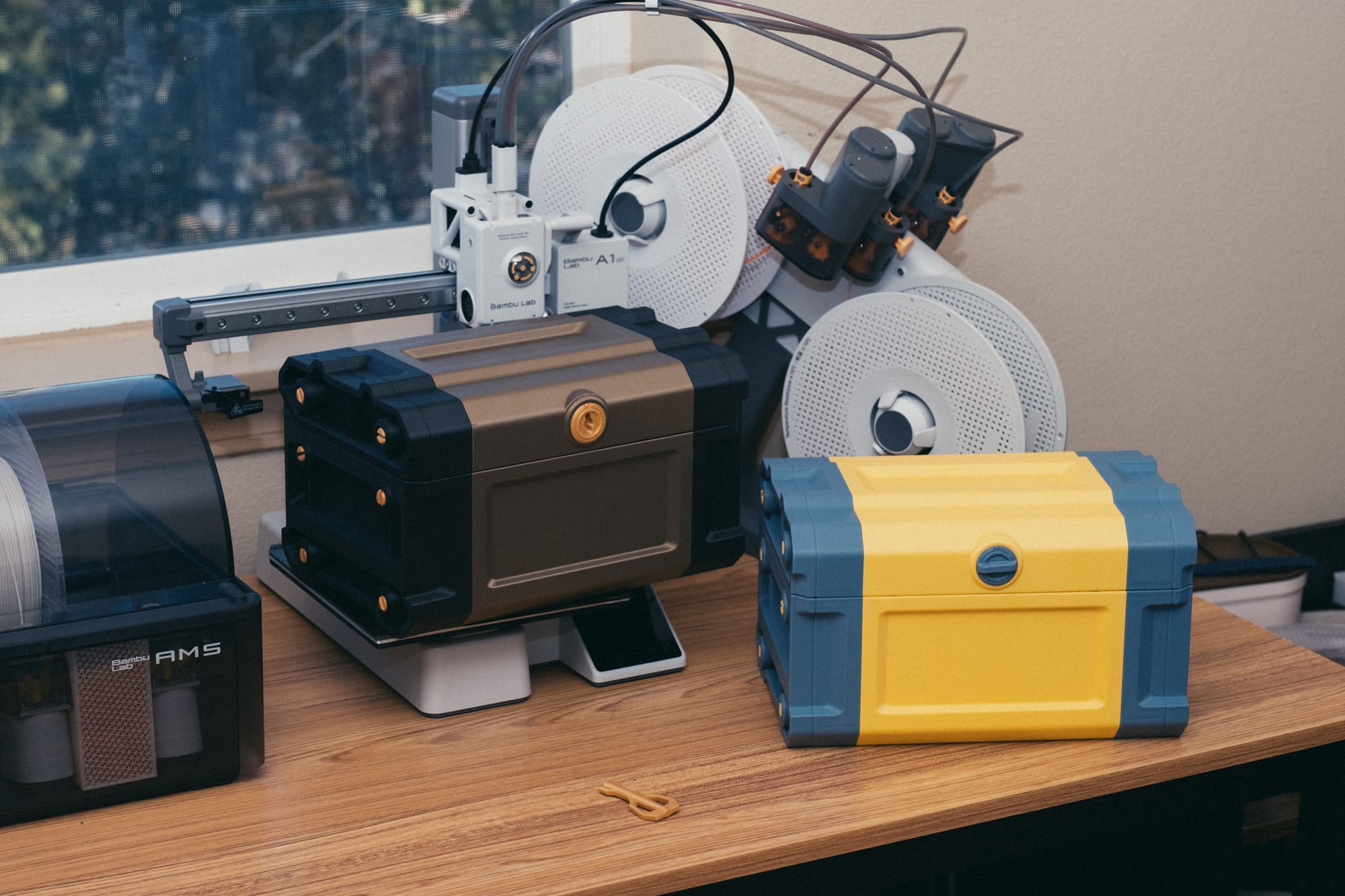

Josh's Bambu Lab 3D Printers

Breaking Boundaries with 3D Printing

"For a long time, 3D printing was mostly a hobby for engineering geeks," Josh said, "but with new advancements, we're seeing things shift. More consumers are getting interested, and the projects are moving beyond gimmicks or proof of concepts."

For Josh, it's about pushing the boundaries of what 3D printing can achieve. His card shuffler project is a perfect example. Frustrated with the low-quality options in stores, he decided to design his own. "You either had cheap, ugly shufflers or super expensive ones," Josh explained. By combining 3D-printed parts with traditional hardware, he created a high-quality shuffler that far surpassed anything available off the shelf.

Josh's Card Shuffler is super popular in the community and has received a lot of great reviews.

Finding the right hardware for these projects, however, can be tricky. In the DIY world, pushing the limits of what's available often means the biggest challenge is sourcing the extra parts. That's why Josh hasn't tackled certain projects yet. "Maker Supply makes it easy," he said. "For a lot of projects, it’s as simple as clicking 'add to cart.'" This resource has been a game-changer for Josh, providing clear guidance on accessible components. "I feel confident using their parts because I know I can design around components people can actually get," he added. His card shuffler, for example, only needed a few simple parts, all of which are now easily available through Maker Supply.

Josh's Tic-Tac-Toe game is another example of his approach. Designed to be colorful and playful, it's a project families could print and take on weekend trips for the kids. His goal was to create something as good as anything found in stores, and he succeeded. The project attracted attention as a glimpse into the future of 3D printing, showing its potential to create real, usable products. "For me, it's not just about making a model," Josh explained. " It's about challenging existing products and pushing the limits of what 3D printing can do."

"Josh is a incredibly talented 3D artist with a knack for seeing details and design in a way that is hidden from the general public. His fine eye for detail and scale is equally matched with his talent! These valuable skills often translate into beautifully rendered 3D printed models that are as solid to hold in person as it is as a 3D object on a computer screen."— Jen Dang, a UX designer, was one of Josh's coworkers from way back.

The design of TicTacToe makes the trip so much more fun.

Making, Breaking, and Creating: Josh's 3D Printing Philosophy

Josh has managed to blend 3D printing into many of his hobbies. From 3D-printable R/C trucks to remote-control climbing cranes, he enjoys taking on big, fun projects. Photography adds another layer to his process, as he often captures detailed product shots of his prints.

Josh is also into photography, and it goes hand-in-hand with his 3D printing projects.

Most weekends, you'll find Josh absorbed in his 3D printing projects. It fills much of his free time, but he wouldn't have it any other way. Weekends give him the space to slow down, reflect, and brainstorm new ideas.

"One of my dream projects is to create a full garden-scale train kit," Josh shared. "While some people have tried this, most aren't complete or well-made. They're more proof-of-concept than functional products."

His advice for newcomers is simple: "Keep trying. Don't get stuck on past mistakes. Sometimes, it's better to start fresh with what you've learned rather than forcing a fix on something flawed." He emphasizes that not every project will be perfect, but learning from mistakes is crucial for growth. Josh also recommends studying existing designs to understand how others build and to pick up on the details they include.

Looking back at Josh's early work compared to now, it's clear how much he has grown with this mindset. Each project has taught him something new, and he’s always striving to improve.

The expanding 3D printing market, along with modern machines, has transformed designs from mere concepts into real, lasting products. As technology advances, 3D printing is giving people the power to create on their own terms, turning dreams into reality.

Take a look at more of Josh's photography – they'll definitely give your day a fresh boost!