Lights-Out, Full Throttle! How Texas A&M Formula SAE Electric Team sped up development with 3D printing

From blank sheet to race-ready. No reruns. No downtime. Just Bambu Lab’s precision and speed...

Engineering is not only a science, but also the art of compromise between strength and weight, cost and performance, time and precision.

In the automotive industry, these trade-offs depend on production scale. Large manufacturers producing millions of vehicles each year balance durability with profitability, refining assembly lines to minimize losses. Their world revolves around economies of scale, standardization, and long validation cycles.

At the other end of the spectrum lies a realm where cost becomes secondary and absolute performance takes priority: extreme weight reduction, rapid iteration, and relentless testing.

This is the world of motorsport - especially its academic, student-driven dimension- where time pressure and limited resources collide with the ambition to compete with professional teams.

Between textbook theory and racetrack reality lies a gap that young engineers must bridge within just a few months.

In academia, designing and building a race car is more than an engineering task; it is a crucible for creativity and problem-solving under tight budgets and deadlines. Each year, a new team must transform a concept into a competitive vehicle within three academic quarters.

Such a compressed path from idea to physical prototype demands manufacturing methods that can keep pace.

Traditional techniques, though proven, are often too slow, too costly, or too restrictive for the bold geometries that can deliver a competitive edge. In this environment, time is the one resource that cannot be bought - and losing it can mean failing to finish before the final deadline.

Until recently, student teams also faced the paradox of 3D printing.

While it promised design freedom, it required levels of calibration and process control far beyond their primary field of study. Dimensional inaccuracies, thermal distortions, and failed prints were common.

Instead of accelerating development, printers often caused delays, forcing future engineers to troubleshoot manufacturing issues rather than focus on vehicle dynamics and system optimization.

Out of this frustration - and the need for a step change in reliability - emerged a shift that, as demonstrated by one American university team, shows how advances in production tools can redefine the limits of student motorsport.

Texas A&M Formula SAE Electric Team

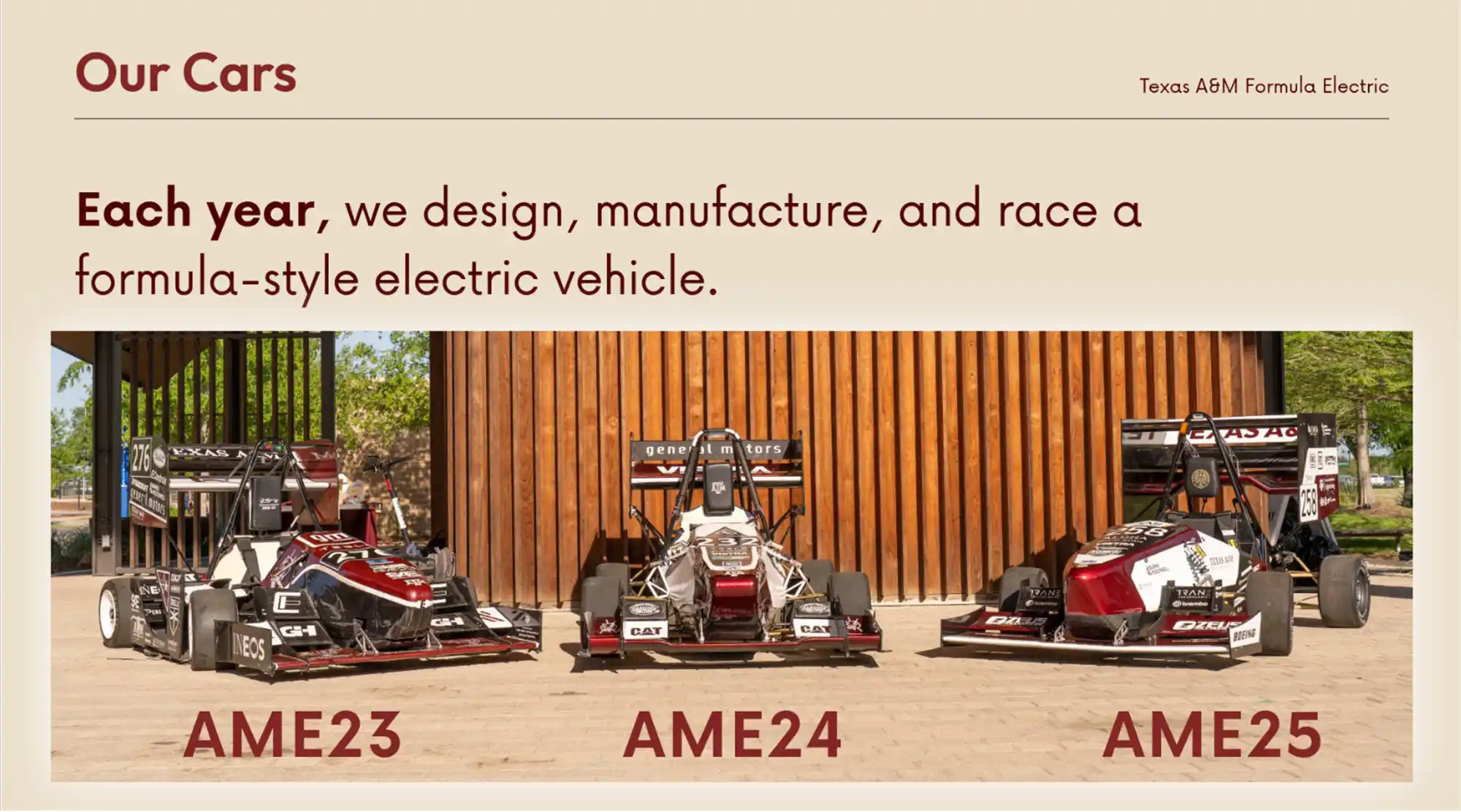

The Texas A&M Formula SAE Electric Team is a student-led engineering organization that designs and builds a fully electric, formula-style race car from the ground up each year.

Operating on a nine-month development cycle, the team transitions annually to a new group of students who take the car from a clean-sheet concept to a fully functional vehicle.

The finished car competes at Formula SAE Michigan at the Michigan International Speedway against nearly 100 universities worldwide, followed by a regional competition at UT Arlington.

For the current season, the team set a clear objective: to establish a reliable vehicle platform and competition strategy capable of placing within the top five percent of all teams at Formula SAE Michigan.

This goal is supported by an emphasis on early rules compliance, structured testing, and thorough validation.

At its core, the program exists to develop capable engineers through direct involvement in the full lifecycle of a high-performance electric race car, while steadily improving the team’s technical foundation year over year.

Common 3D printing challenges

Prior to adopting Bambu Lab 3D printers, the team faced recurring challenges common to student engineering environments. Warpage, inconsistent tolerances, and frequent print failures made work with 3D printers unpredictable.

Printers required constant supervision, and successful prints depended on meticulous tuning of parameters that often changed with time and environmental conditions.

These limitations slowed prototyping cycles and reduced confidence in printed parts.

As a result, the team relied more heavily on alternative rapid-prototyping methods, which constrained design freedom and increased overall development effort.

The lack of reliability also made it difficult to integrate 3D printing into time-critical phases of the build season.

The Bambu Lab solution

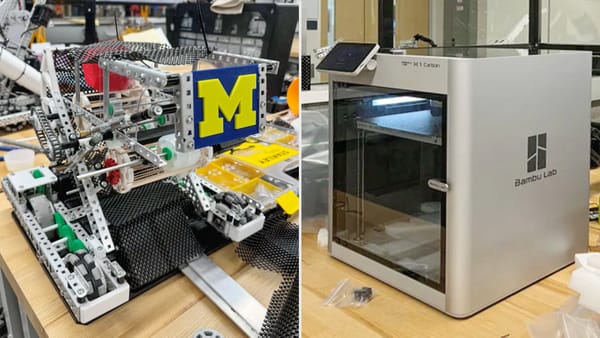

The team started to work with Bambu Lab P1S and X1C printers. The P1S was selected first due to its strong reliability, print quality, and speed, making it suitable for a wide range of day-to-day prototyping needs.

The in-chamber image of P1S (left) and X1C (right) during operation

As designs became more complex and material requirements more demanding, the team identified limitations when working with advanced engineering filaments.

With the addition of the X1C, the team gained the capability to print more intricate parts using challenging materials without extensive calibration.

This expanded material compatibility allowed the team to take on components that were previously difficult or impractical to produce in-house.

Integrating Bambu Lab printers significantly changed how the team approaches design and manufacturing.

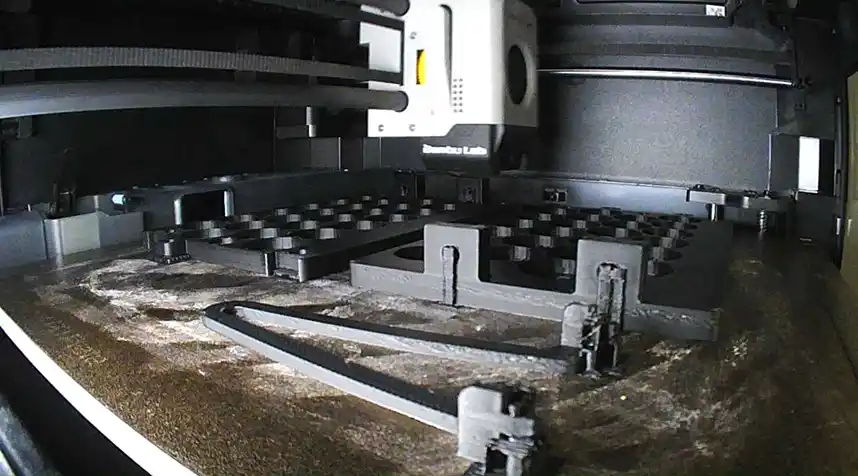

The printers enabled near “lights-out” operation, allowing jobs to run without continuous supervision.

Team members could start prints remotely as soon as designs are finalized and monitor progress through the mobile application, rather than traveling to the shop, which is located off main campus.

This shift shortened iteration cycles substantially. Parts can now be designed, printed remotely, and be ready for use by the time team members arrive at the shop later the same day.

Improved support removal and print consistency also reduced post-processing effort. Designs no longer require extensive compromises to accommodate fragile supports, enabling greater geometric freedom and faster integration of printed parts onto the car.

Results

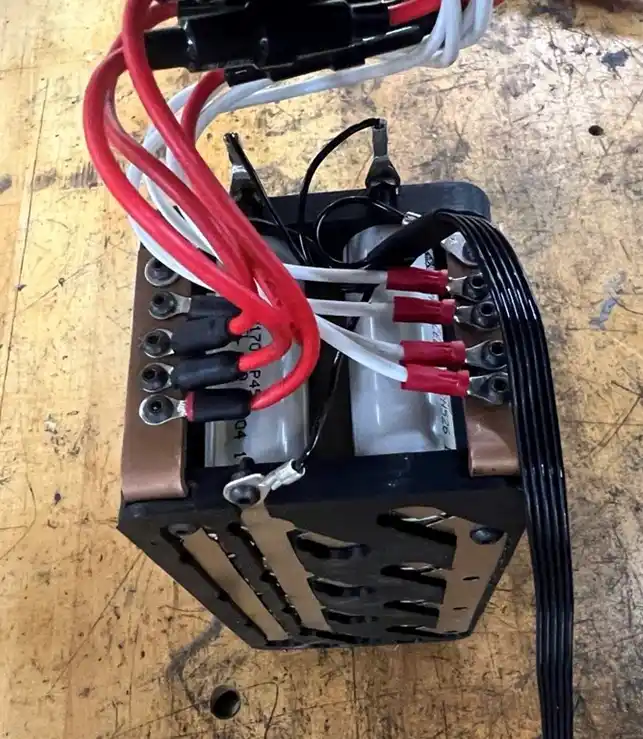

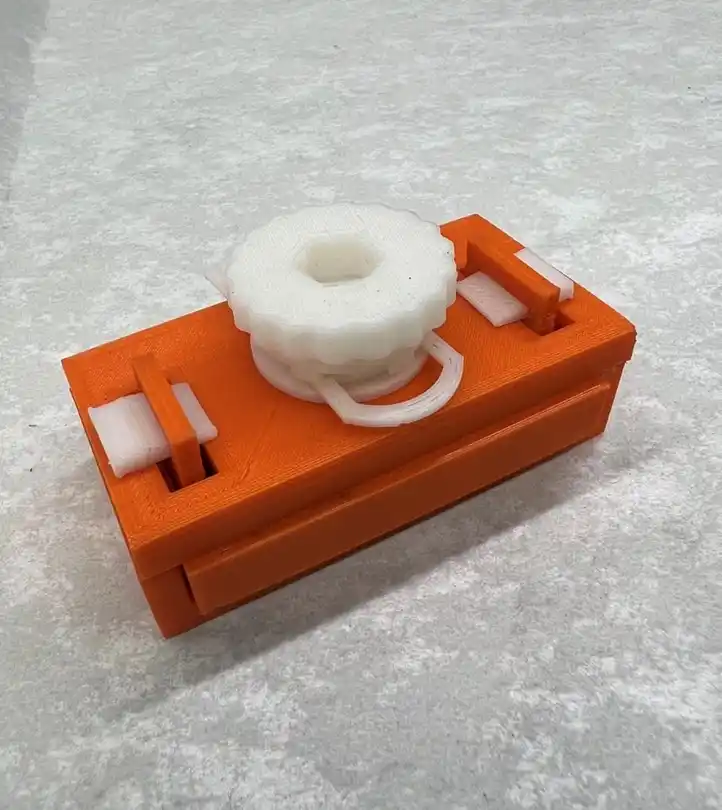

One of the most demanding components produced using the Bambu Lab X1C is the battery segment cell structure. This part features complex geometry on multiple faces and must be printed using UL94-V0 rated, fire-retardant filament to meet safety regulations.

Such materials are prone to shrinkage and warping on many printers, often requiring extensive calibration.

The X1C produced these parts with high dimensional accuracy and surface quality without extensive setup.

Bambu Lab's 3D prinitng technology enabled the team to integrate reinforcement features in all directions within a single component, reducing both weight and assembly complexity compared to traditional manufacturing methods.

Low Voltage Battery frame, completely manufactured by 3D printing

Beyond structural components, the team regularly prints consumables such as resin mixing heads for composites work, molds, and tooling. Plans are underway to expand printing into jigs and mounts for chassis welding, simplifying fabrication and improving consistency during the manufacturing season.

In parallel with material selection, the team has explored process improvements across multiple areas. The composites group has refined post-processing techniques to improve mold surface finish and release, including sanding, polishing, primer application, and wax treatments.

High Power Conductors and Maintenance Plugs printed with multiple materials, including flame-retardant materials (left) and the actual installation of this accessory (right)

The team has also evaluated different support strategies, including dissolvable PVA supports, to achieve cleaner part finishes.

Infill patterns and densities have been studied to identify the best strength-to-weight balance, aligning with the team’s broader effort to reduce mass across the vehicle.

Bambu Studio plays a central role in these workflows, particularly through its tight integration with the printers.

Remote monitoring, filament management, and efficient job control are especially valuable for a team operating with limited shared shop time.

The introduction of the Bambu Lab X1C and P1S led to a substantial increase in printer utilization, with machines operating nearly continuously and minimal idle time. The high print success rate and consistent quality have eliminated reprints to date, cutting the team’s prototype manufacturing timeline roughly in half.

By avoiding failed prints and reducing manual oversight, the team has been able to focus more time on engineering decisions and validation rather than troubleshooting manufacturing issues.

The printers have become dependable production tools rather than experimental assets. In the future, this will further promote their new vehicle development process.

Future outlook

The Texas A&M Formula SAE Electric Team plans to integrate 3D printing into the core R&D and spare parts system of the racing team. This aims to achieve rapid iterative design, on demand manufacturing of spare parts, quick response at the race site, and overall cost optimization, thus enhancing the racing car's performance and the team's competitiveness.

Specific plans include establishing a digital inventory of spare parts, enabling the in team or on site printing by partner suppliers of commonly used small parts.

Additionally, printing compliance standards for key life cycle parts (such as sensor mounts, duct clamps, and wire harness brackets) will be formulated and incorporated into the race support process.

The team plans to expand its use of 3D printing technlogy beyond prototyping and into final, functional components, including structurally relevant parts produced through metal AM.

The ability to design complex internal geometries without the constraints of traditional machining is seen as particularly valuable for future suspension and chassis-related components.

BambuLab will also continue to cooperate with them to further deepen the application of additive manufacturing in the field of racing cars.