MOCA x Maker's Supply: A Custom Filming Rig Kit

A designer needed a better phone cage. So he made one, and worked with the Maker's Supply team to turn it into a buildable kit for others.

For years, designer @thrutheframe relied on store-bought camera rigs. Bulky, expensive, and never quite what he needed. And as smartphone filming took off, the accessories didn’t get much lighter or more customizable.

So he set out to design his own phone cage, the MOCA. Something lightweight, modular, and accessible.

“What began as a simple phone cage project became something greater: a thoughtfully curated kit that removes barriers for makers.” – @thrutheframe, Designer of MOCA

Design Considerations Behind MOCA

MOCA was designed to be practical, adaptable, and easy to build. @thrutheframe began by measuring the dimensions of popular smartphones, aiming for a size that would work comfortably with most devices.

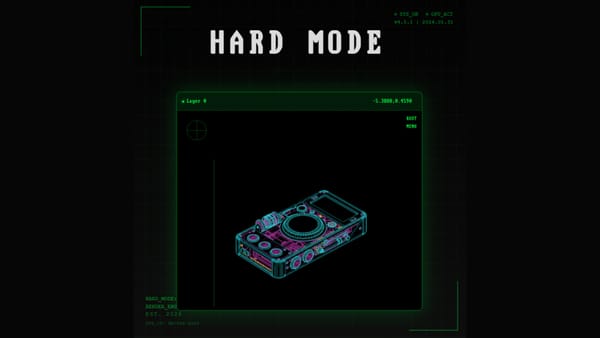

Digital design on the left, fully assembled MOCA on the right.

For the clamp, he landed on a simple solution: stretchable rubber bands. They’re easy to adjust, easy to replace, and let users fine-tune the grip by adding or removing bands.

When it came to mounting accessories, he leaned on familiar standards; cold shoes for lights and mics, NATO rails for modular grips, and ARCA-Swiss plates for tripods.

"This ensures users can integrate their favourite store-bought accessories with MOCA seamlessly," @thrutheframe shared.

The goal was to make something that felt familiar and easy to integrate, without requiring new tools or gear.

Hardware: The Missing Pieces

Like many 3D printing projects, MOCA needed more than just plastic. Screws, nuts, magnets, rubber bands... small parts that hold everything together, but aren’t always easy to source.

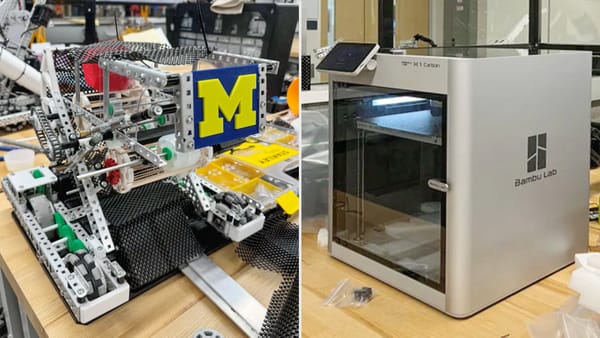

Left: The 3D printed parts and the MOCA Plus kit. Right: A fully assembled MOCA kit.

One complication was the mix of standards.

“Photography gear traditionally uses imperial hardware, like 1/4-20 threads for tripods,” @thrutheframe explains. “But it’s easier to CAD design and source hardware in metric units.”

MOCA had to do both. Mounting points followed imperial standards to stay compatible with off-the-shelf gear, while the rest of the design used metric components.

The result? A growing list of SKUs and a frustrating experience for makers trying to track them all down.

“The design worked, but sourcing the hardware was becoming a barrier.”

Bringing It Together with Maker's Supply

Sourcing individual screws, nuts, and magnets from multiple sellers was tedious, and often expensive. It also meant shipping several parts across different parts of the world, which wasn’t ideal from a sustainability perspective.

That’s where the idea of a hardware kit came in.

A few customized MOCA rigs from MakerWorld users @user_4202103578, @smooki, @_cr3di_, @LetMe_Print, and @str8xtc.

@thrutheframe worked with the Maker's Supply team to finalize the bill of materials, based on the parts already in inventory and those still needed.

They exchanged test samples, sorted out specific hardware requirements, and made sure the final kit included a few spares.

As designers, we often work with whatever hardware is on hand, but creating a proper maker's kit demands more rigor," @thrutheframe shared. "Through consistent communication, we aligned on why certain parts needed specific specifications to ensure MOCA would function flawlessly."

With the hardware handled, MOCA became much more approachable. Instead of piecing things together from different stores, makers can focus on the best part: printing, building, and filming!