On-site 3D printing in modern healtcare: how XO Armor is bringing personalized orthotics closer to patients

Bambu Lab X1C is helping to transform healthcare, enabling faster personalization, shorter lead times, and on-site production

When thinking about 3D printing in medicine, what usually comes to mind are photopolymer 3D printers producing dental applications, surgical tools, or anatomical models from resins, as well as metal 3D printers used to manufacture titanium implants. At most, bioprinting is also mentioned, though it still remains a highly niche and specialized method used almost exclusively for research in medical laboratories.

Meanwhile, contrary to common assumptions, FFF-type 3D printers have also been used in serious medical applications for many years, which is particularly evident in the area of user-specific solutions.

For example, in rehabilitation the importance of personalization continues to grow, as standard products rarely meet all patient needs. Every injury, anatomy, or activity level often requires a different approach, and the ability to quickly produce tailored components can directly influence comfort, treatment effectiveness, and recovery time.

Similar challenges occur in elite sports, where not only performance matters, but also injury prevention and rapid athlete recovery.

At the same time, medical institutions and sports teams operate in environments where response time and equipment availability are critical. Traditional ordering and manufacturing processes can extend waiting times by days or even weeks, which in many cases is difficult to accept.

This is why demand is increasing for solutions that make it possible to move part of the production process directly into clinics, practices, or training facilities.

Against this backdrop, companies are emerging that build their business models around speed, personalization, and local production.

One example of this approach is XO Armor, an organization focused on using 3D printing technology to create customized protective and orthotic solutions.

Its work demonstrates how combining modern hardware, specialist expertise, and practical user needs can translate into a real transformation in how care and performance-supporting equipment are delivered.

XO Armor Technologies

XO Armor is redefining orthotic and protective equipment through on-site, 3D-printed solutions tailored to the high-performance needs of athletic, medical, and military sectors.

Founded in 2019 to serve elite athletes with custom injury protection, the company quickly gained traction for its rapid and precise orthotic manufacturing approach. XO Armor's core advantage lies in enabling healthcare and athletic professionals to produce personalized splints, braces, and guards on-site-typically within an hour.

The challenge: speed and quality

As the company scaled across industries, speed and reliability became critical performance metrics. XO Armor needed a 3D printing solution that could deliver fast turnaround times without compromising on quality.

Their users-athletic trainers and medical clinicians-depended on streamlined workflows and compact equipment that fit seamlessly into space-constrained environments like training rooms or clinics.

Key challenges included slow print times with legacy equipment, setups that were not user-friendly for busy practitioners, and the need for small-footprint devices that did not compromise on functionality.

The solution: Bambu Lab X1C

XO Armor adopted the Bambu Lab X1C 3D printer as its primary hardware for both internal production and on-site client use. The decision was driven by the X1C's combination of print speed, quality, and ease of use.

The printer offered several direct benefits, including print times that were 30% faster and enabled clinicians to deliver same-day care, high-quality output that met the company's standards for patient-ready devices, and a compact, user-friendly design well suited for on-location installations.

Clinicians could now print fully customized orthotic devices in under an hour-reducing patient wait times from 7-10 days to same-day turnaround.

Results

Since implementing Bambu Lab's X1C printers, XO Armor has seen measurable improvements in operational efficiency and client satisfaction.

Key outcomes include a 50% reduction in clinician costs achieved by replacing outsourced device fabrication with on-site 3D printing, significant time savings particularly in emergency care scenarios where immediate device availability is crucial.

Also, easier printer setup and integration for end users reduced technical barriers and accelerated adoption. The XO team achieved better utilization of small spaces thanks to the X1C's compact design.

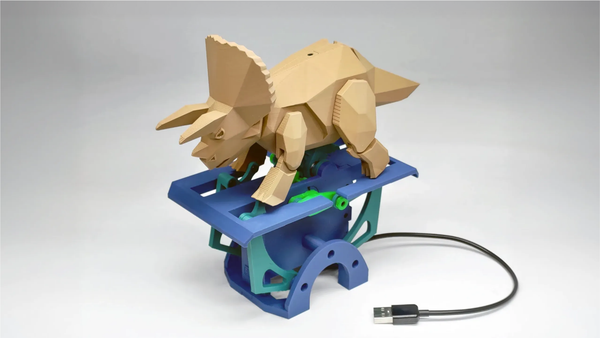

XO Armor uses the printers to fabricate a wide range of protective and rehabilitative devices using PLA and TPU materials. Their catalog includes hand and wrist splints, ankle-foot orthotics, and athletic guards-custom-fitted and created on demand.

Future outlook

Beyond materials, XO Armor is actively testing and refining its slicing methods, printing techniques, and post-processing workflows to further enhance device quality and efficiency.

Their interest in the evolving 3D printing space includes exploring AI integration for design and production, multi-material printing capabilities, larger build volumes, and smarter connectivity options such as 5GHz Wi-Fi and enterprise network support.

XO Armor's integration of Bambu Lab's X1C 3D printers has played a central role in transforming its delivery model-from reactive care based on supply chains to proactive, same-day orthotic fabrication. The result is a more efficient, flexible, and patient-centered service model.

As XO Armor continues to scale into new industries, its collaboration with Bambu Lab remains foundational to its growth and innovation roadmap.