Proto21 3D Prints Record-Breaking Restaurant Interior Using 10.2 Tons of Filament

Dubai-based manufacturer creates massive architectural installations, showcasing industrial-scale 3D printing for luxury commercial spaces.

Proto21 is making history by setting the Guinness World Record for the largest 3D printed structure, one of the boldest applications of additive manufacturing to date.

“We have achieved a world record in the 3D printing industry! This is not only a milestone in Proto21's growth but also an important milestone in the evolution of 3D printing technology.” – Pir Arkam, Founder and CEO of Proto21

A Massive, 6-Month Project

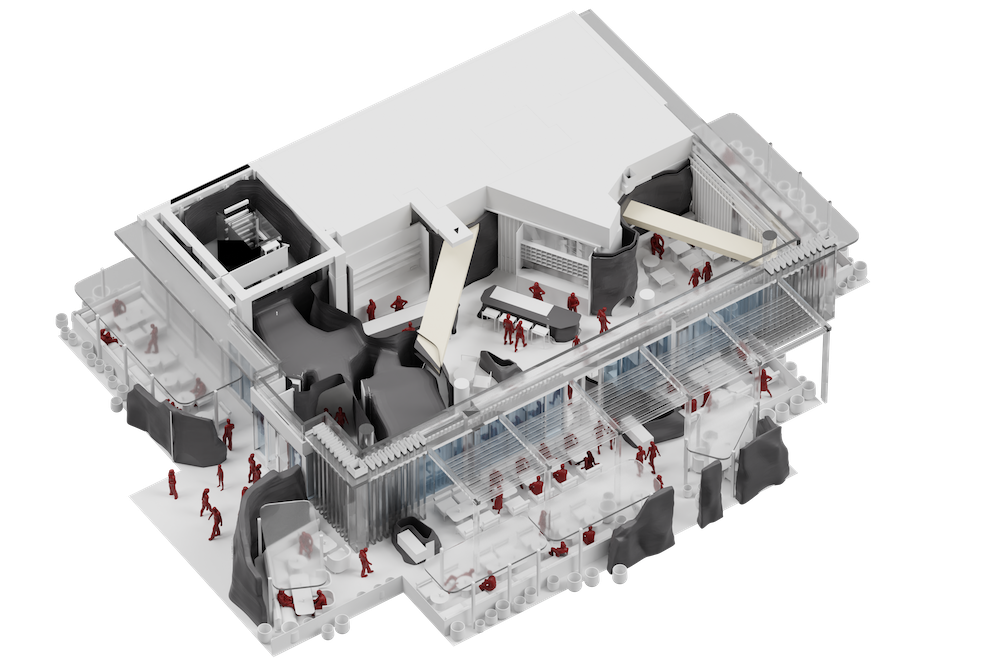

With over 10,000 kilograms of 3D printed material, spanning an immense 1,190 square meters and totaling 38 cubic meters, this project is truly on another level.

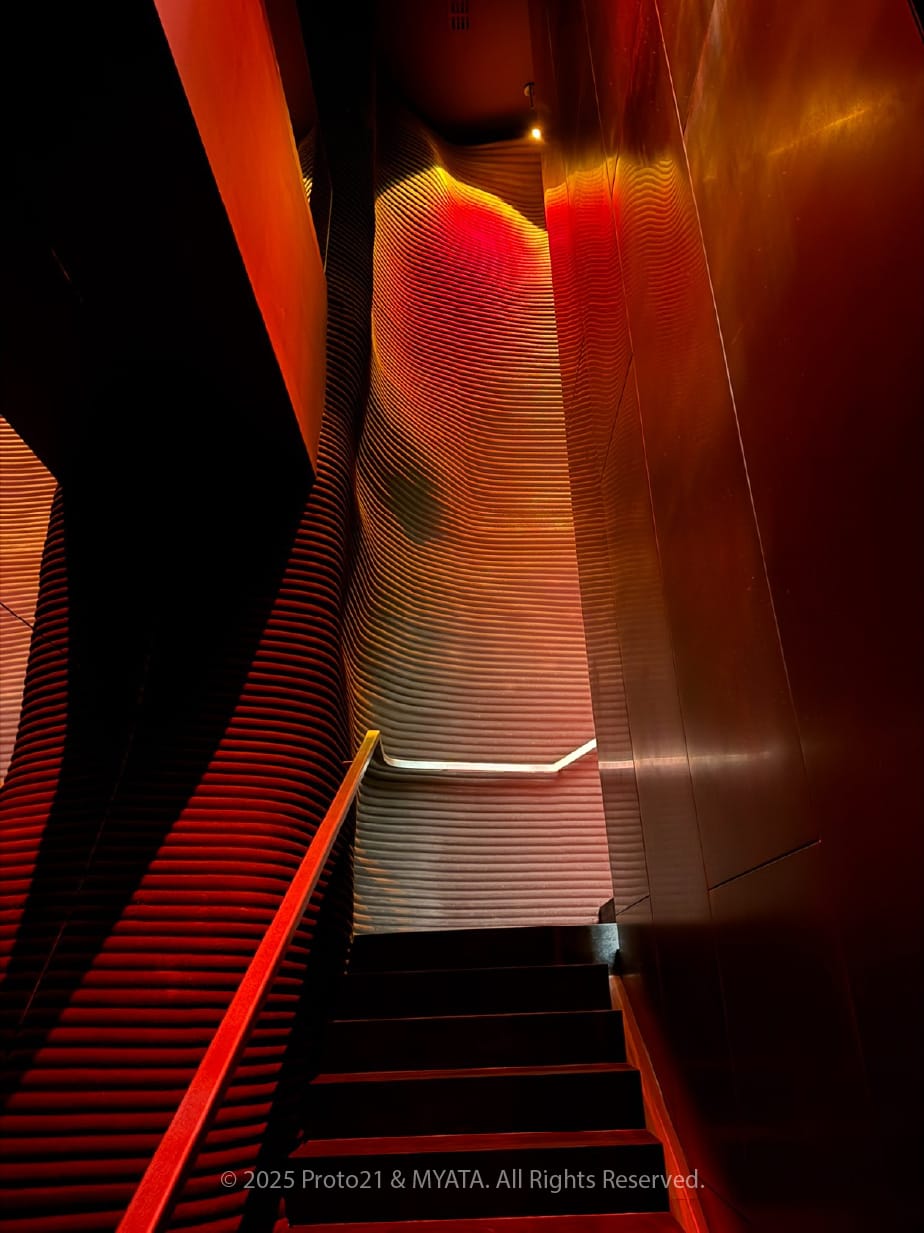

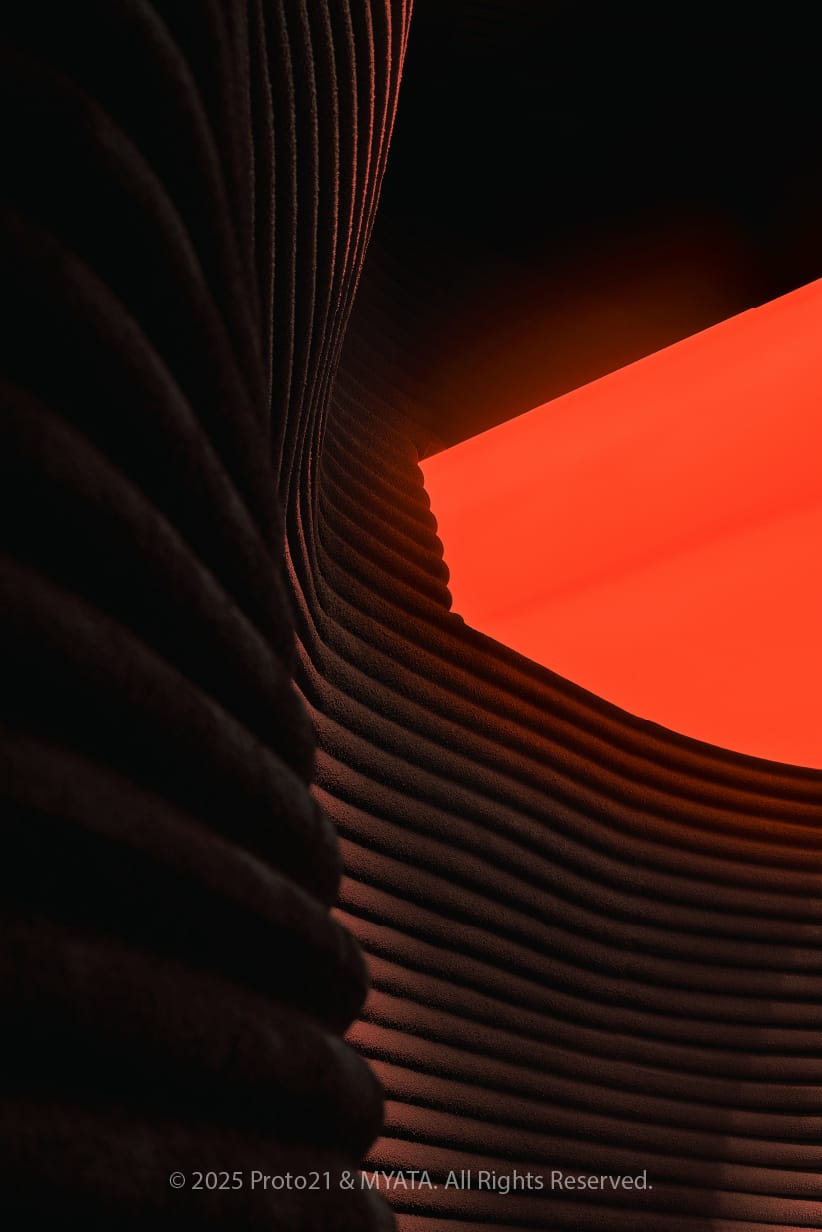

The installation decorates the luxurious MYATA Platinum restaurant in Dubai’s City Walk, with canyon-inspired designs finished in a natural sand texture.

Inside MYATA Platinum Dubai and its new, canyon-inspired installation.

While this achievement is impressive in scale, it's equally remarkable in terms of technical sophistication. The installation's 23 structures are composed of over 27,700 3D printed parts, requiring meticulous design and assembly.

3D illustrations of all the MYATA Platinum restaurant and its 3D printed structures.

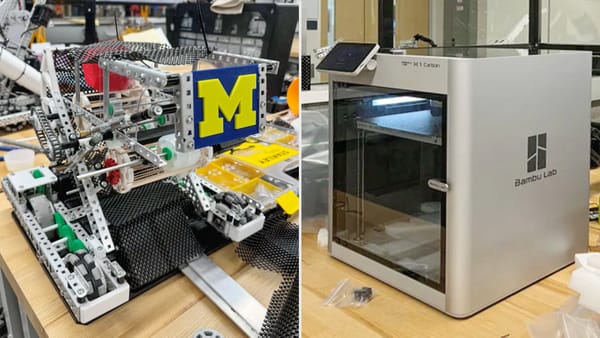

For three months, Proto21’s printers ran nonstop, logging over 160,000 hours of printing and sourcing every last spool of filament in Dubai. Their fleet includes 158 3D printers, including 70 from Bambu Lab, allowing them to balance speed and quality. A robotic arm printer was used for the outdoor elements, while FDM and SLA technologies handled the detailed indoor components.

The scale of the project created significant supply chain challenges. Proto21 consumed filament at such a rate that it disrupted their supplier network, requiring exclusive production runs to meet deadlines.

Material selection also played a crucial role in the project’s success. For indoor elements, Proto21 mainly used PLA+ for its strength and ease of post-processing. Outdoors, the extreme climate meant switching to PPGF, a glass-fiber-reinforced polypropylene that could endure intense heat without warping.

The view from outside the MYATA restaurant.

Proto21’s team meticulously executed every step of the process, from design to final finish. The specifics of their assembly technique remain undisclosed, adding another layer of intrigue to this already remarkable project!

Thriving on Challenges

Proto21 is no stranger to taking on ambitious projects. Known as the “911 for UAE production”, they’ve built a solid reputation in Dubai, taking on tight-turnaround and large-scale projects that others won’t touch.

“We’ve taken on projects where the timeline seems impossible,” says Arkam. “But thanks to our advanced fleet and the creativity of our team, we deliver results faster than anyone expects.”

When Adidas needed a 32-meter-long 3D printed store facade for the Dubai Mall, Proto21 made it happen in five weeks. Another major project? A 6-by-4-meter relief map for the UAE Ministry of Defense, built entirely from Google Earth data.

And, often, clients come to Proto21 with only a vague idea, a rough concept, or even just dimensions. The team transforms these ideas into fully realized, tangible results.

More art and interior design projects 3D printed by Proto21.

Proto21’s Backstory

From a young age, Pir Arkam was drawn to art and technology, always experimenting with ways to build and create. But it wasn’t until a university exchange program at the University of Huntsville, Alabama, that he discovered 3D printing, an encounter that changed everything.

Arkam spent the next few years getting hands-on, experimenting, learning, and figuring out how to turn it into something bigger. In 2018, he relocated to Dubai, starting Proto21 from his bedroom with a single machine.

Fast-forward six years, with a $100k investment from Joseph Group, and the company has evolved into a powerhouse. It now employs 45 people and operates the largest 3D printing fleet in the Middle East and Africa.

“I’ve been lucky to have a team that trusts me, even when I take on projects that seem impossible,” Arkam says. “Our hard work, dedication, and creativity are the foundation of everything we achieve.”

Got a bold project in mind? Reach out to Proto21 to bring it to life. And if Pir inspired you to build your own fleet of 3D printers, Bambu Lab has the tools to get you started.