Red Wolf Technology: Revolutionizing On-Demand Phone Accessories with Bambu Lab

How Red Wolf Technology built a scalable in-store accessory printing workflow with Bambu Lab printers, materials, and software.

About Red Wolf Technology

Red Wolf Technology empowers retail and repair stores to manufacture phone accessories— such as custom phone cases, screen protectors, and polish kits— on-demand, in-store. Their three flagship solutions are:

- Primo Print3D: Prints flexible, durable, fully customized phone cases while customers wait.

- Primo Protect: Cut perfect-fit screen protectors for any device.

- Primo Polish: Restores scratched phone screens to like-new condition.

By bringing production local and just-in-time, Red Wolf minimizes waste, lowers costs, accelerates turnaround, and unlocks new revenue for retailers.

The Challenge

Before adopting Bambu Lab printers, Red Wolf faced two major hurdles:

1. Traditional Manufacturing Limits

- Injection Molding: Required expensive tooling, long lead times, and large minimum runs— making small-batch, on-demand production impossible.

2. Existing 3D Printer Shortcomings

- Speed & Quality: Most desktop FDM printers were too slow, costly, or produced parts unfit for retail sale.

- Reliability: Frequent failures and inconsistent output undermined customer confidence.

These constraints made in-store, real-time customization of phone accessories unviable, until Red Wolf discovered Bambu Lab.

The Bambu Lab Solution

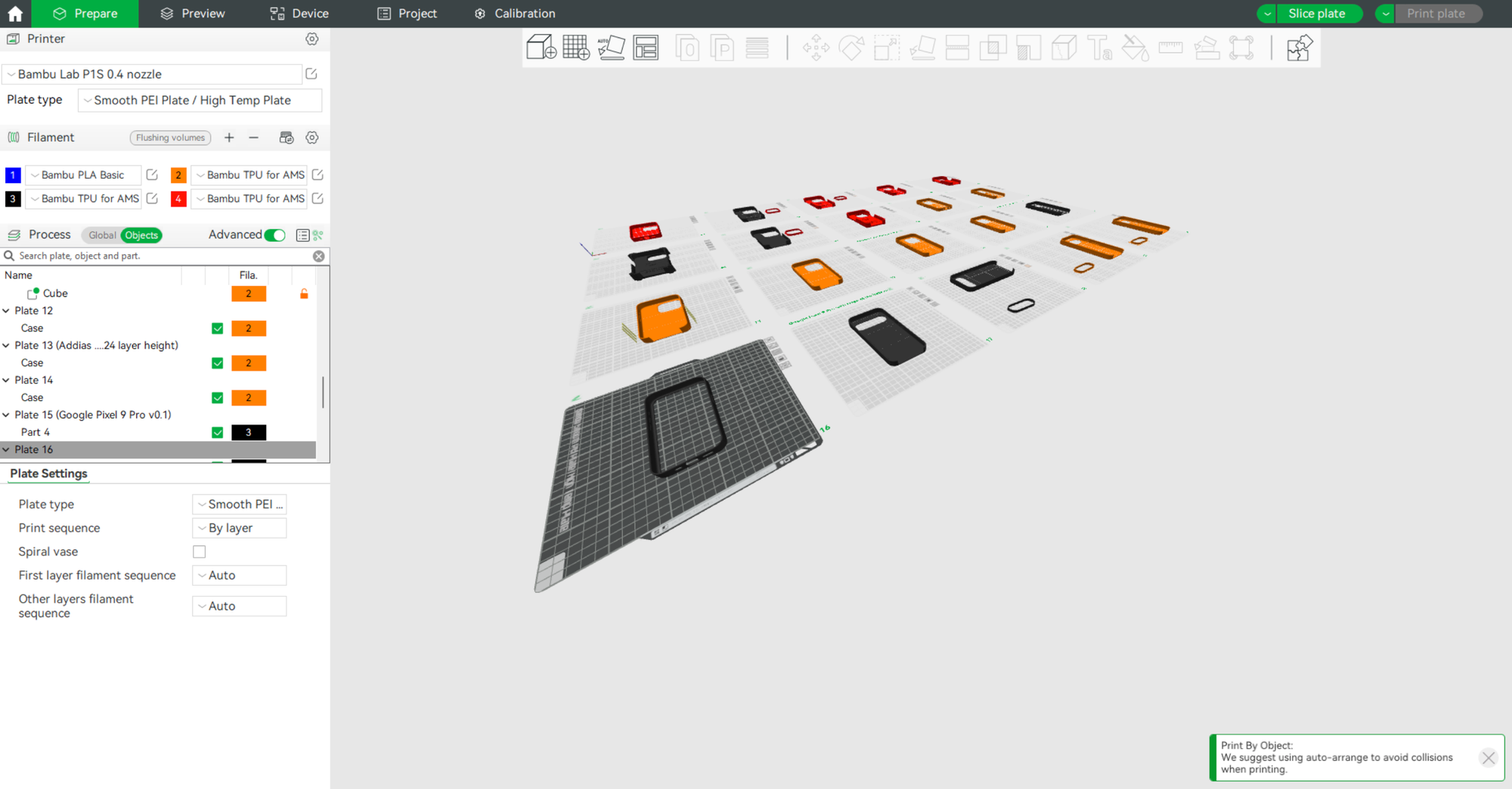

Red Wolf Technology has standardized its operations on a fleet of Bambu Lab printers— X1C, P1S, P1P, A1, and A1 Mini— to bridge rapid prototyping and scalable retail production.

Red Wolf’s in-house prototyping makes seamless in-store printing possible.

In their central prototyping lab, the X1C and P1 series leverage CoreXY mechanics and ultra-high acceleration (up to 50,000 mm/s²) to handle multi-material iterations and precision jig fabrication at speeds other desktop systems can’t match.

For in-store deployment, the fully enclosed P1S— valued for its integrated AMS, robust build volume, and balanced performance-to-cost ratio— powers on-demand printing at global partners such as MediaMarkt and CPR Cell Phone Repair.

By integrating each machine into Red Wolf’s custom Primo Print3D platform via the Bambu Farm Server SDK API over a secure LAN, they achieve seamless job queuing, centralized material management, and real-time status monitoring across all locations.

Implementation & Workflow

- Design & Prototyping: In their headquarters, Red Wolf’s R&D team uses Bambu Studio and OrcaSlicer to finalize case models.

- Centralized Job Management: A custom, API-driven print-farm application schedules and monitors print jobs across 20+ machines, ensuring optimal utilization and minimizing downtime.

- In-Store On-Demand Printing: Retail staff launch Primo Print3D, guiding customers through selecting device model, color, and pattern. They then send the job directly to the local P1S.

- Post-Processing & Delivery: Once printed (in as little as 15-20 minutes), cases are ready for pick-up, eliminating inventory guesswork and wasted stock.

Results & Benefits

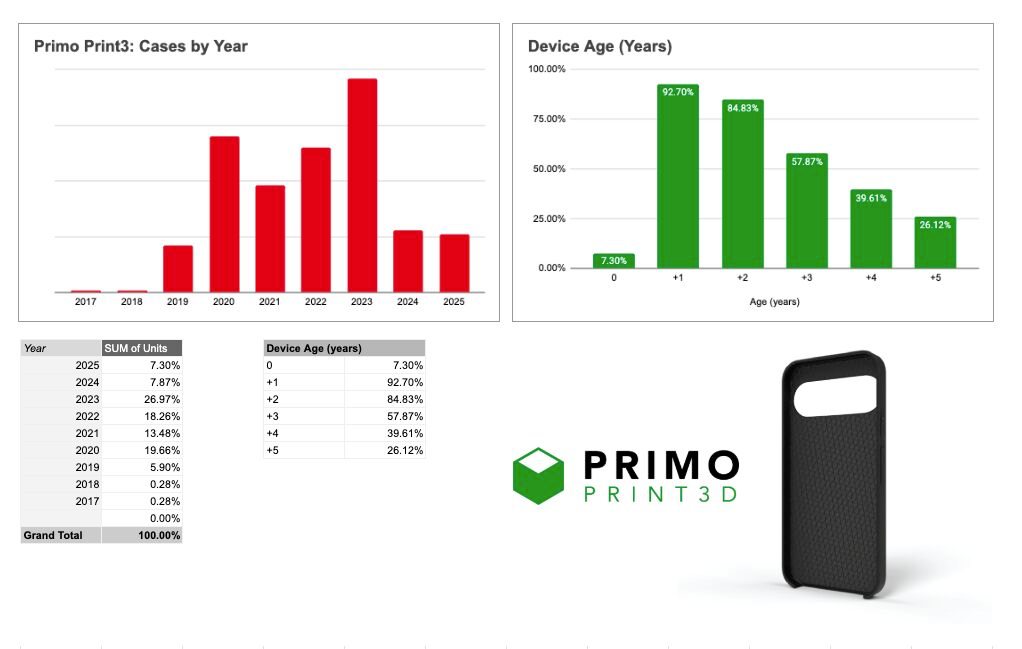

- Viable On-Demand Business Model: Bambu Lab’s speed and quality made in-store case printing a reality, creating hundreds of millions in new revenue opportunities.

- Inventory & Waste Reduction: 100% of prints are customer-driven; no overstock, no dead inventory.

- Broader Device Coverage: From the newest releases to older models, Red Wolf meets demand others can’t. 92.7% of cases were for phones launched in the past year, 84.8% within the past two years, and 26% were for much older devices— well outside what traditional supply chains typically support.

- Operational Efficiency: Centralized queue management cut manual printer hand-offs by over 60%, boosting throughput and uptime.

- Material Advancements: Transitioning from PLA to Bambu TPU for AMS delivered the flexible, high-quality cases customers demanded, with the reliability of the automatic material system.

Looking Ahead

Red Wolf continues to explore emerging hardware, software, and materials to expand its on-demand offerings.

They’re working on deeper integration with the Bambu Farm Server APIs to reduce reliance on the Bambu Handy app and streamline LAN-mode switching.

The team is also piloting workflow improvements, like automated cache clearing and expanded API capabilities, to boost efficiency and maintain the fastest, most flexible retail printing experience.

Exploring on-demand production for your own business? Bambu Lab’s hardware, materials, and open API ecosystem are built to scale with you.