The Icon Redefined: meet the P2S - a completely reengineered version of the ultra-productive P1 Series

P2S combines the legacy of the iconic P1-Series with next-generation technologies from the H-Series

We are proud to announce the launch of the P2S - a redefined version of the iconic P1 Series, which have become the backbone of printfarms around the world.

Completely reengineered from the ground up, the new P2S integrates a rich set of Bambu Lab's technologies for significantly enhanced and even more reliable ease of use.

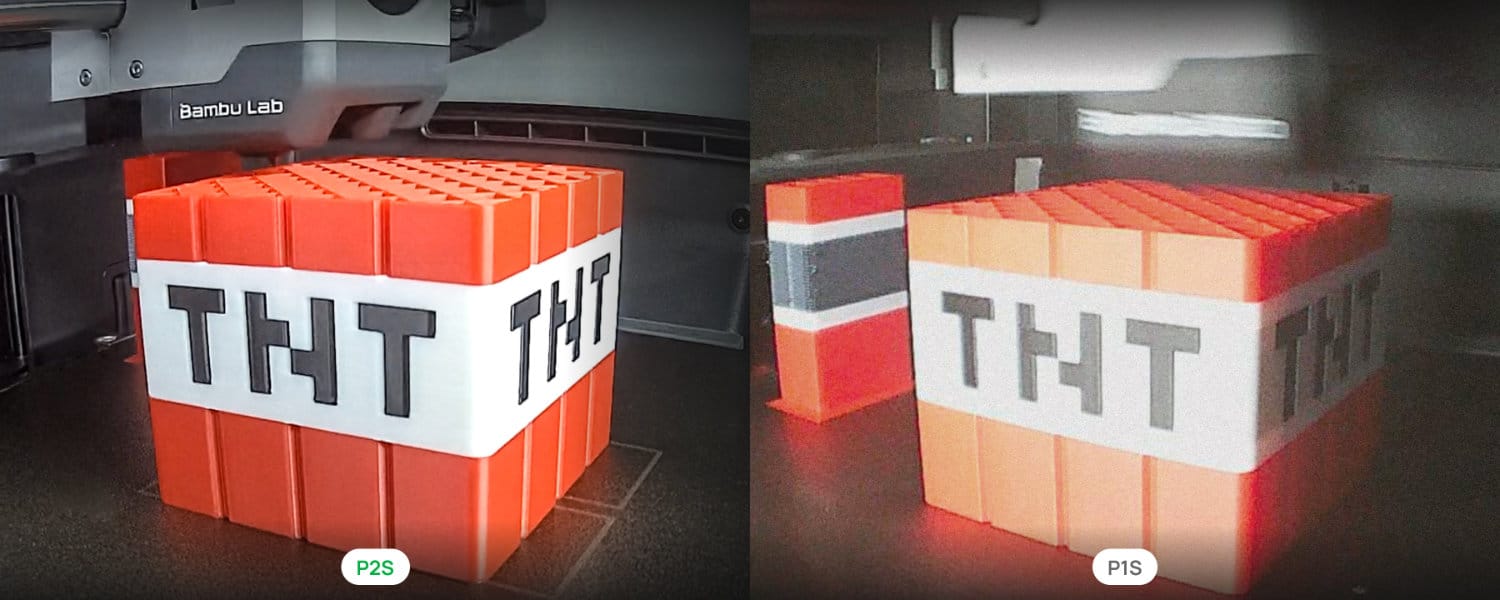

The P2S combines the production-floor-proven, compact design of its predecessors with a series of innovations recently introduced in the H2D and H2S models. It features breakthrough technologies such as the DynaSense extruder and Active Airflow system.

It is also equipped with a 2nd-Gen UI on a 5-inch touchscreen, advanced AI error detection, 1080P high-rate live view, and an exceptionally convenient and reliable quick-swap nozzle system with a simple one-click mechanism.

And yet, with all those features, the P2S comes at the amazingly affordable price of just €519 (tax included), and the P2S Combo at just €749 (tax included)!

The Birth of a Modest Icon of Sheer Productivity

Although the Bambu Lab P1-Series is just two and a half years old, it has already become a cult, iconic 3D printer - one that raised productivity to previously unreachable levels.

Bambu Lab entered the scene in 2022 with the X1, a high-speed, sensor-packed printer that integrated cameras, lidars, and the AMS system for multi-color printing - all at a fraction of the cost of traditional prosumer machines. It set a new benchmark and completely disrupted the balance of the market.

Just a few months after the market launch of the X1 series, Bambu Lab introduced a more affordable version of the X1 - the P1P.

While it retained the core technology, it lacked certain elements (e.g., no side panels, or a smaller monochrome control panel). Essentially, the P1P differed little from the “higher” X1 version, aside from being dedicated to more traditional filaments (PLA, PETG, ASA, etc.).

And then something incredible happened…

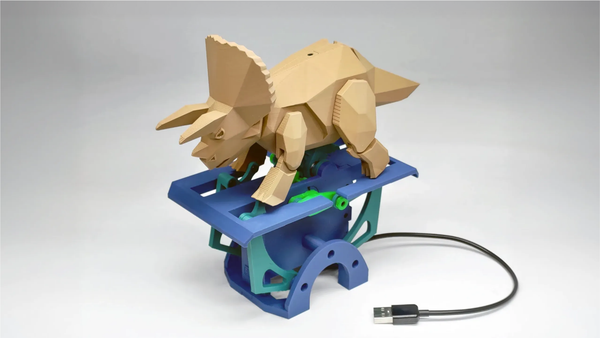

This stripped-down but still fully functional version of the X1 not only held its ground but proved to be ideal for mass production of end-use products. Its ease of use, reliability, and low purchase price inspired people worldwide to build printfarms with dozens of 3D printers, operating continuously 24/7.

On social media, amateur videos began circulating, showing ordinary warehouses or modest production spaces filled with dozens - or even hundreds - of P1Ps. All of them working at full throttle! All producing parts - sometimes tens of thousands every week!

In July 2023, Bambu Lab introduced an expanded version of the P1P - the P1S - featuring a factory-closed build chamber and a series of additional upgrades.

Thanks to the P1P and P1S, a new wave of 3D printing entrepreneurs emerged, creating businesses built on ultra-affordable and ultra-reliable systems, and scaling up colossal production units powered by hundreds of 3D printers.

The P Series, with its compact size, outstanding performance, and the best price-to-quality ratio on the market, became the foundation of an entirely new branch of the 3D printing industry.

Redefining the Icon

In 2025, Bambu Lab introduced a new generation of 3D printers - the H2 Series (H2D, H2D Pro, H2S, and the yet-to-be-released H2C, scheduled for launch later this year). The H2 Series represents an entirely new benchmark for productivity, designed for truly demanding applications.

But the company never intended to stop there. The P Series still remains one of the cornerstones of sales, and its iconic legacy simply demanded a refresh and adaptation to Bambu Lab’s new proprietary technological standards.

The P2S is a unique fusion of all the best qualities of its remarkable predecessors with the modernity and innovation of the H2 Series.

Key Features of the New P2S 3D Printer:

2nd-Gen UI on 5-Inch Touchscreen

The P2S comes with a fully upgraded touchscreen and a powerful processor running our intuitive second-generation UI. It offers smoother interactions, richer graphics, and clearer step-by-step guidance. Simple, intuitive, and easy to use—even for beginners.

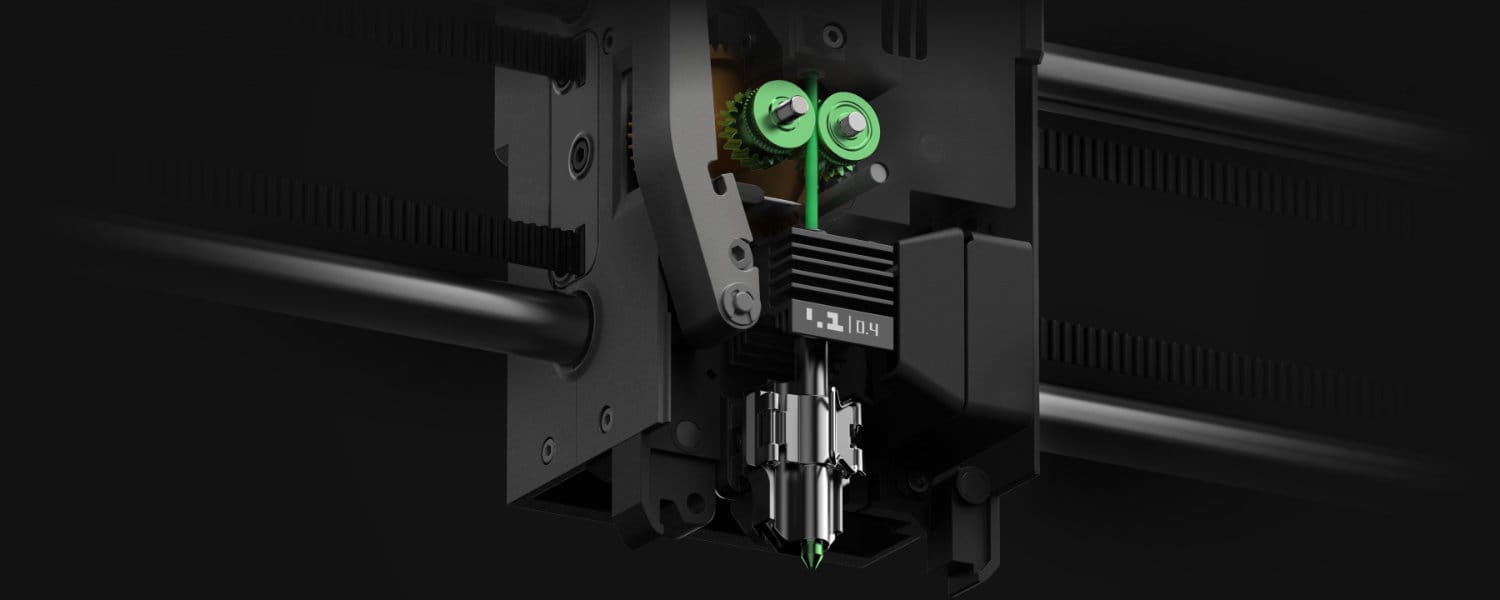

PMSM Servo Extruder

The PMSM servo extruder delivers up to 8.5 kg of maximum extrusion force - 70% more than its predecessor - dramatically improving stability at high flow rates. Moreover, our servo architecture samples resistance and position at 20 kHz, actively detecting filament grinding and clogs in real time.

Auto Flow Dynamics Calibration

The P2S uses a high-resolution, high-frequency eddy current sensor to calibrate flow dynamics. Intelligent algorithms actively adjust the flow rate based on these readings, ensuring precise, consistent extrusion across every layer and corner.

Adaptive Airflow Cooling

The Adaptive Airflow System draws in cool air directly from outside the chamber, significantly improving cooling efficiency. This allows users to print low-temperature filaments with the doors closed - without compromising overhang quality or risking nozzle clogs.

Adaptive Airflow Heat Preserving

A flap-controlled Adaptive Airflow System efficiently retains heat within the chamber while filtering internal air through a high-performance carbon filter. This enables confident use of high-performance, warp-prone filaments while maintaining clean, safe air quality in the workspace.

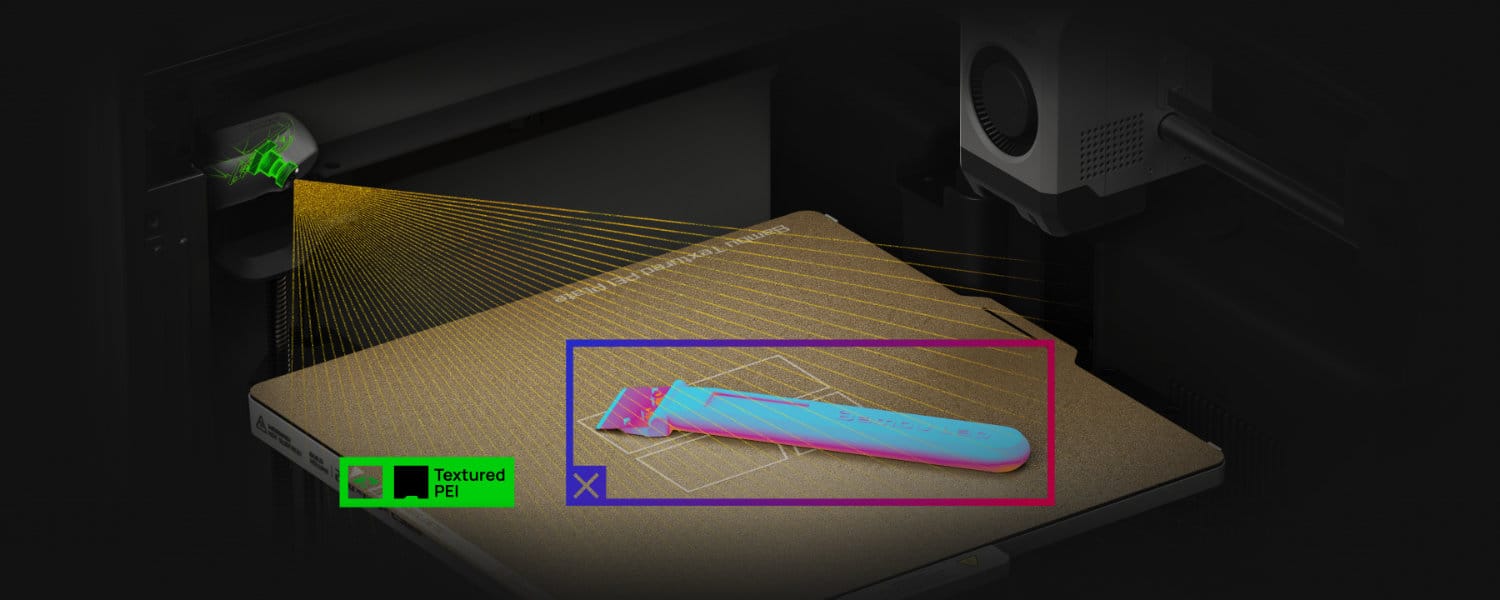

AI Error Detection

The P2S introduces advanced AI-powered computer vision that actively detects common printing issues such as spaghetti, nozzle blobs, and air printing. It also cross-checks the build plate and nozzle type against slicer settings, ensuring a safe and accurate start to every print.

1080P High-Rate Live View

Enhanced LED lighting dramatically improves the clarity of live video and timelapses. Paired with a high-frame-rate camera, users can easily monitor the printer remotely and capture stunning timelapses for social media sharing.

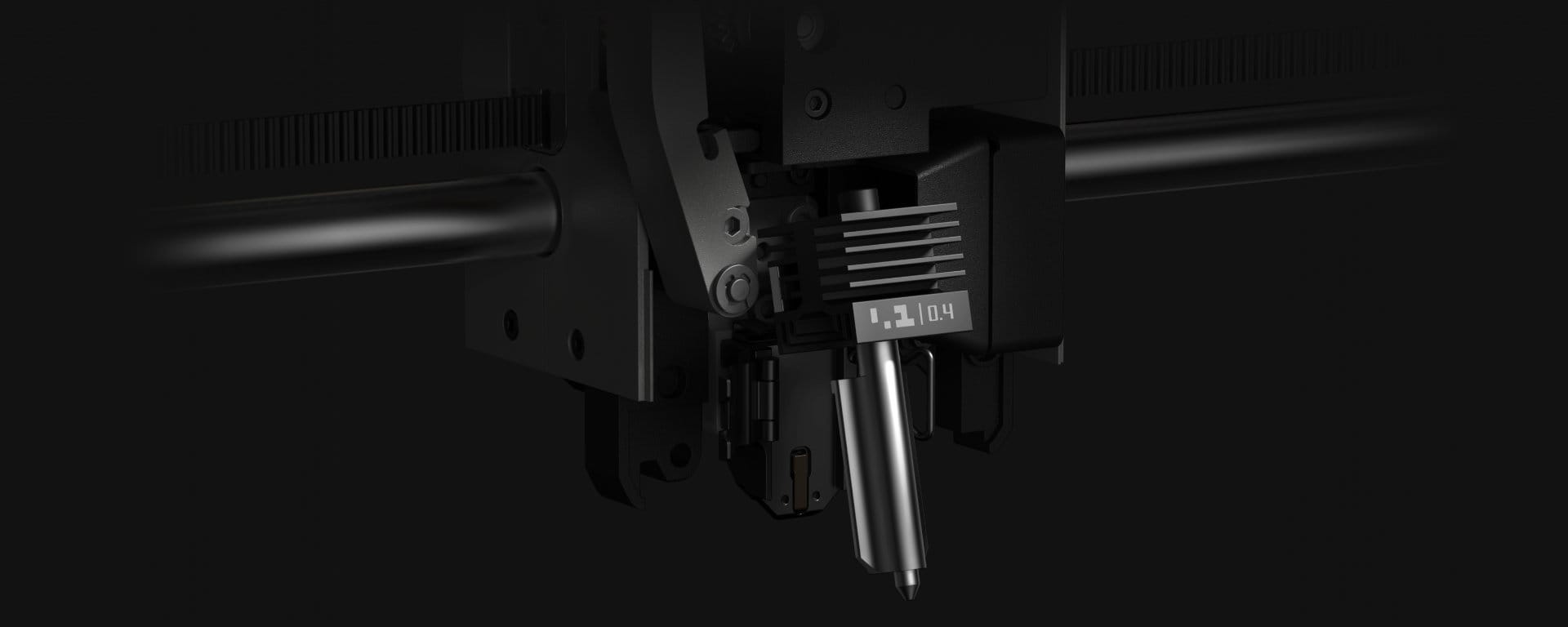

Quick-Swap Hotend

The P2S features a quick-swap nozzle design with a simple one-clip mechanism that releases the entire nozzle and heatsink assembly - no wiring connections required.

AMS 2 Pro

The P2S Combo comes equipped by default with the highly reliable multi-color AMS 2 Pro system, featuring enhanced filament drying. A pioneering active venting system dries filament 30% faster than sealed heating, maintaining low humidity for superior storage and print quality.

Other Specifications:

- Build volume: 256 × 256 × 256 mm

- Maximum nozzle temperature: 300°C

- Default nozzle diameter: 0.4 mm (also supported: 0.2, 0.6, 0.8 mm)

- Built-in filament cutter

- Maximum heatbed temperature: 110°C

- Sensors:

- Door sensor

- Filament run-out

- Filament tangle

- Filament odometry

- Power loss recovery

Final note

The introduction of the P2S does not mark by any means the discontinuation of the P1S model, which will remain available in Bambu Lab's offer and fully supported.